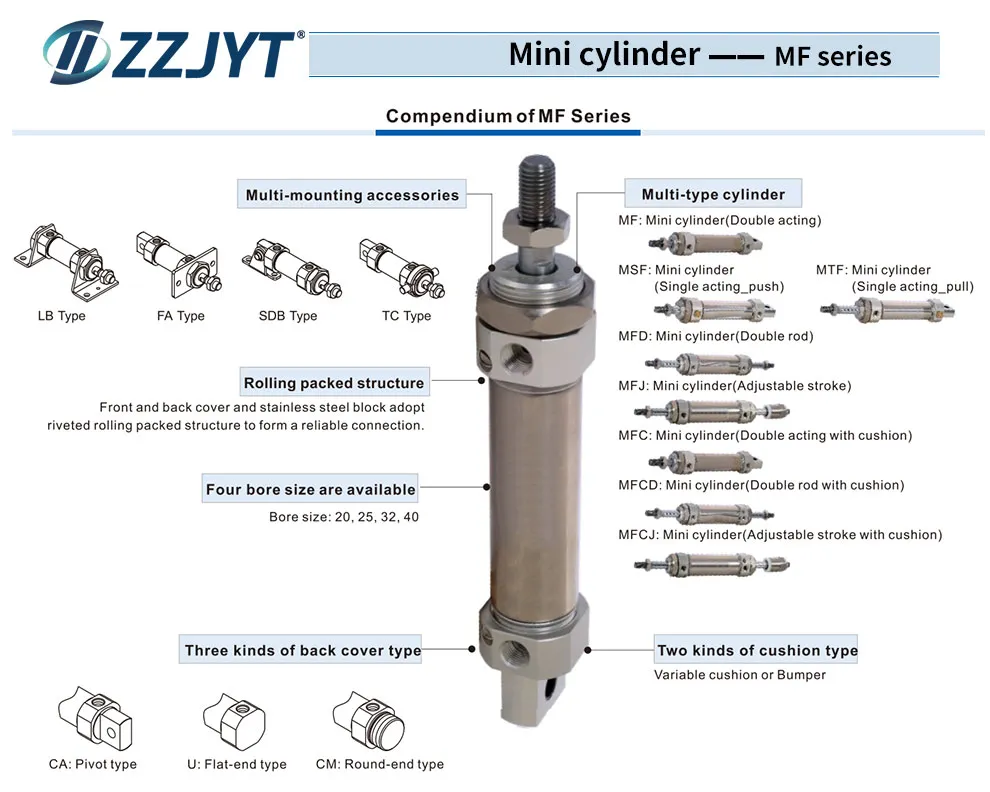

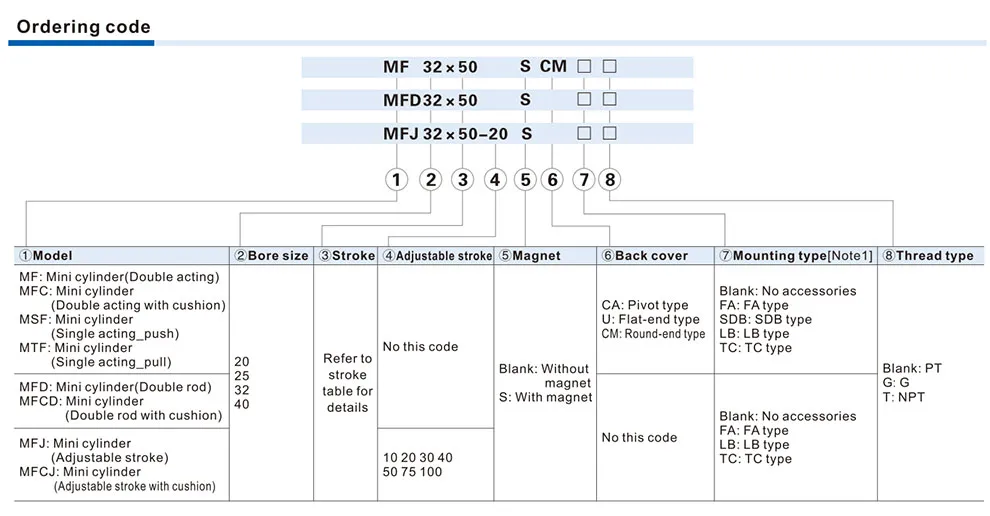

The MF Series pneumatic mini cylinder is designed as a versatile actuator optimized for modern automation needs. Its compact profile allows for use in restricted spaces while delivering consistent linear motion through pneumatic power. Constructed with quality materials for long-lasting durability, the MF Series supports both single-acting and double-acting configurations. With options for magnetic sensing, adjustable cushioning, and various mounting styles, this mini cylinder fulfills the automation industry’s demand for precision, reliability, and ease of integration.

Main Features and Advantages

Compact pneumatic mini cylinder with bore sizes commonly ranging from 12mm to 40mm

Available in single-acting and double-acting types with adjustable stroke lengths

Robust aluminum or stainless steel body options for corrosion resistance and durability

Magnetic piston sensor compatibility for position detection and automation control

Adjustable cushioning to reduce noise and enhance operational smoothness

Lightweight design facilitating ease of installation in limited spaces

Wide operating temperature range supporting versatile industrial environments

Multiple mounting options including foot mount, flange mount, and rod end designs

| Bore size(mm) | 20 | 25 | 32 | 40 | |

| Acting type | Double acting、Double acting with cushion、Single acting | ||||

| Fluid | Air(to be filtered by 40 μ m filter element) | ||||

| Operating pressure | Double acting | 0.15~1.0MPa(22~145psi)(1.5~10.0bar) | |||

| Single acting | 0.2~1.0MPa(28~145psi)(2.0~1.0bar) | ||||

| Proof pressure | 1.5MPa(215psi)(15bar) | ||||

| Temperature ℃ | -20~70 | ||||

| Speed range mm/s | Double acting 30~800 Single acting 50~800 | ||||

| Cushion type | MFC/MFCD/MFCJ Series:Variable cushion; Other series:Bumper | ||||

| Port size | 1/8″ | 1/4″ | |||

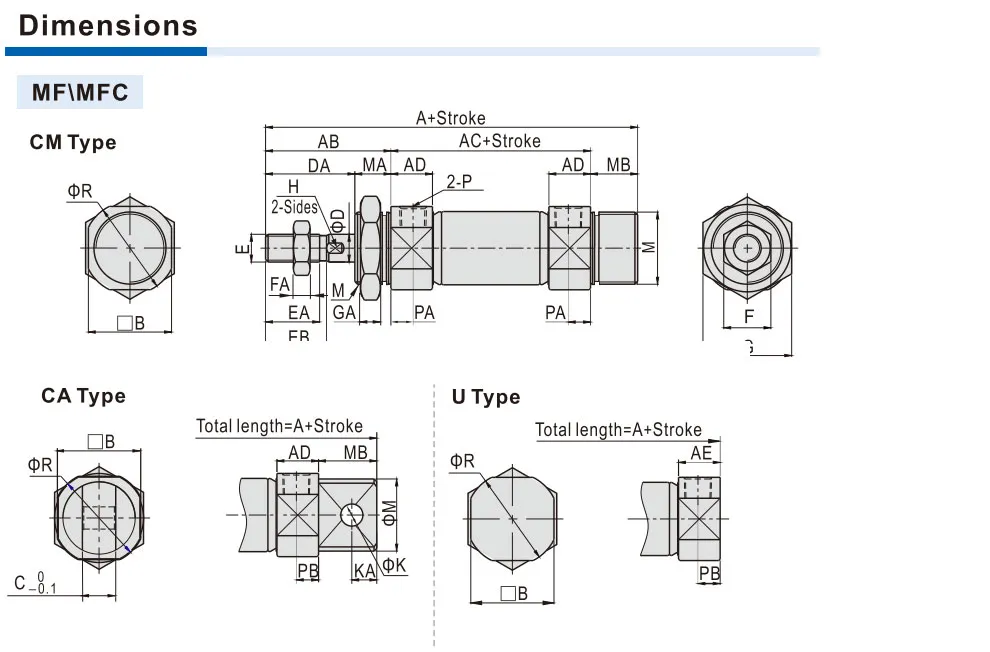

| Bore size/Item | A | AB | AC | AD | AE | B | C | M | MA | MB | ||||

| Back cover | CM | CA | U | CM | CA | CA | CM | |||||||

| 20 | 116 | 124 | 103 | 41 | 62 | 14.5 | 14.5 | 25 | 12 | M20*1.5 | 20 | 14 | 21 | 13 |

| 25 | 120 | 128 | 108 | 45 | 62 | 14.5 | 15.5 | 30 | 12 | M26*1.5 | 26 | 14 | 21 | 13 |

| 32 | 122 | 136 | 110 | 45 | 64 | 14.5 | 15.5 | 34.5 | 20 | M26*1.5 | 26 | 14 | 27 | 13 |

| 40 | 154 | 165 | 138.5 | 50 | 88 | 21.5 | 22 | 42.5 | 20 | M32*2.0 | 32 | 16 | 27 | 16 |

| Bore size/Item | D | DA | E | EA | EB | F | FA | G | GA | H | K | KA | P | PA | PB | R |

| Back cover | ||||||||||||||||

| 20 | 8 | 27 | M8*1.25 | 16.5 | 18 | 12 | 6 | 26 | 8 | 6 | 8 | 9 | 1/8″ | 7.5 | 7.5 | 29 |

| 25 | 10 | 31 | M10*1.25 | 20.5 | 22 | 17 | 6 | 32 | 8 | 8 | 8 | 9 | 1/8″ | 7.5 | 8 | 33.5 |

| 32 | 12 | 31 | M10*1.25 | 20.5 | 22 | 17 | 6 | 32 | 8 | 10 | 10 | 12 | 1/8″ | 7.5 | 8 | 37.5 |

| 40 | 16 | 34 | M14*1.5 | 22.5 | 24 | 19 | 8 | 41 | 10 | 14 | 10 | 12 | 1/4″ | 11 | 11.5 | 46.5 |

Installation Steps and Maintenance

Confirm bore size and stroke length based on the automation task requirement.

Choose an appropriate mounting method suitable for the system layout.

Connect pneumatic tubing using clean, regulated air supply to prevent contamination.

If equipped with magnetic sensors, securely connect wiring and test sensor output.

Adjust cushioning settings to optimize stroke smoothness and reduce wear.

Periodically inspect seals, piston rods, and cylinder body for leakage or damage.

Perform lubrication as directed by manufacturer guidelines, especially in high-cycle environments.

Maintain cleanliness around the cylinder to avoid foreign material interference.

Detailed Applications

The MF Series pneumatic mini cylinder is utilized extensively in automated production lines, packaging machinery, laboratory automation, electronics assembly, and precision tooling industries. Its compact size and fine control characteristics make it ideal for pick-and-place mechanisms, sorting equipment, clamping systems, and anywhere space constraints require efficient actuator design. Magnetic sensor options enhance feedback accuracy necessary for smart manufacturing and Industry 4.0 integration.

How to Select the Right MF Series Mini Cylinder

Evaluate bore size and stroke length requirements based on load and travel distance.

Choose between single-acting or double-acting design per application motion needs.

Select material (aluminum or stainless steel) according to the work environment and corrosion resistance needed.

Determine if magnetic piston detection is essential for your control system.

Ensure compatibility with existing pneumatic and automation setup including mounting preferences.

Factor in operating temperature range and cycle frequency to select the most durable model.

Request a Quote Now

Our team will get back to you within 24 hours.