The meaning of the barb of the barb connector in pipeline terminology

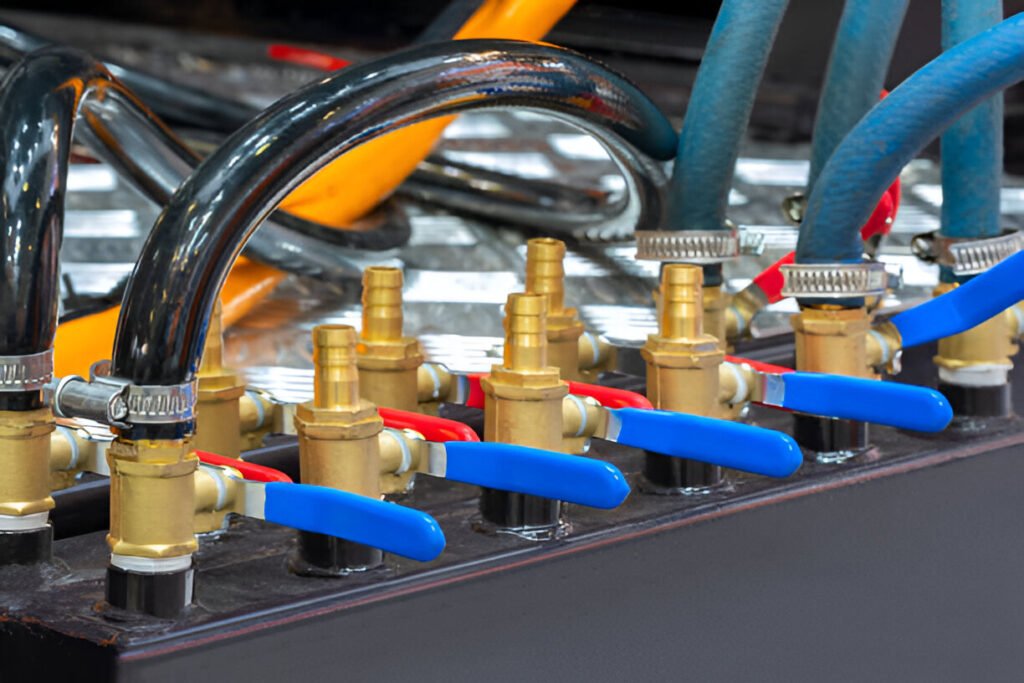

Proper copper barb connector design can significantly improve the reliability and safety of pipe connections. The barb is an important structural feature of pipe connectors. It refers to the sharp protrusions designed on the surface of the connector after the connector is inserted into one end of the pipe. These protrusions can firmly grasp the inner wall of the pipe and prevent the pipe from detaching from the connector. The sharpness, surface finish and angle of the barb will affect the overall quality of the connection.

Comparison and selection of different materials

When choosing pipe connectors, you need to consider the characteristics and applicability of different materials:

- Brass: economical and suitable for general fluid handling and pneumatic applications, but poor corrosion resistance

- Stainless steel: excellent corrosion resistance, suitable for occasions with higher requirements, but more expensive

- Plastic: light and good insulation, but poor strength and high temperature resistance

It is very important to choose the right connector material considering factors such as cost, application environment, and medium characteristics.

Which pipes are suitable for barb connector

Barb connectors can be widely used to connect a variety of pipes:

- PVC pipe: Barb connectors are an economical choice for connecting PVC pipes. The barb and bead design helps to strengthen the connection

- PE pipe: The unique barb design at the bottom of the copper barb connector can prevent it from loosening and falling off after being inserted into the PE pipe, improving the quality of PE pipe connection

- Metal pipe: Copper barb connectors are also suitable for metal pipe connections, providing corrosion-resistant and durable connections

Different pipes have different material properties. Choosing a suitable barb connector can give full play to its advantages and obtain a reliable connection effect.

How barbs enhance the reliability of pipeline connections

- Bite force: The tip of the barb can penetrate deep into the inner wall of the pipe, generating a large bite force to resist the axial tension of the pipe

- Anti-falling off: The barb cooperates with the stop groove on the connector to prevent the connector from falling off the pipe after being stressed

- Sealing: The close fit between the barb and the inner wall of the pipe can improve the sealing performance of the connection and reduce the risk of leakage

- Vibration resistance: The barb structure increases the rigidity of the connection and can remain stable and reliable even when the pipe vibrates

Through reasonable barb design and precise manufacturing process, the role of the barb can be maximized to obtain high-quality pipe connections.

Applicable pipes and application scenarios of copper barb connectors

PVC pipe:

- Pipeline connection of garden irrigation system

- Connection accessories of aquarium water supply pipeline

- Pipes for general fluid transportation and pneumatic equipment

PE pipe:

- Connection between floor heating pipeline and water distributor

- Connection parts of gas pipeline

- Connection accessories of water supply pipeline system

Metal pipe:

- Connection between refrigerant copper pipe and condenser

- Gas pipeline connection in medical equipment, such as ventilator, anesthesia machine, etc.

- Gas connection inside analytical instruments, such as mass spectrometer, chromatograph, etc.

Copper barb connector plays an important role in various pipeline connection applications due to its excellent mechanical properties and wide applicability, and it is worth giving priority to engineers when designing pipelines.