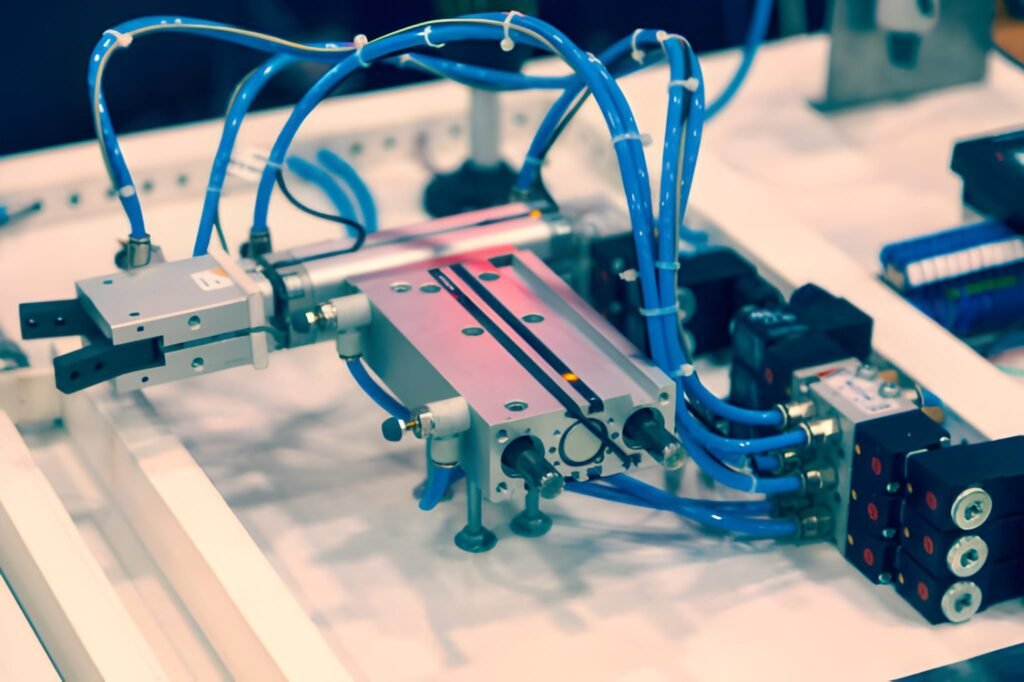

Have you ever wondered what makes a Double Rod Cylinders so popular in industrial automation? Well, these clever devices are everywhere — quietly powering precise, balanced motion in countless machines. A Double Rod Cylinder, also known as a double rod pneumatic cylinder, features two rods extending from opposite sides of the piston. This unique construction helps deliver stable, force-balanced movement in both directions.

If you’re in manufacturing or engineering, understanding how Double Rod Cylinders work and why they’re favored can help you choose the best actuator for your application. Let’s explore their advantages and dive into the most common and exciting use cases. Along the way, I’ll share insights that will help you optimize your machinery performance and even boost cost efficiency.

Structural Features of Double Rod Cylinders

Double Rod Cylinders have a distinctive design: two piston rods emerge from opposite ends of the cylinder barrel, unlike a single rod in traditional pneumatic cylinders. This dual-rod setup offers several crucial benefits:

- Force Symmetry: Because rods extend from both sides, the cylinder provides equal force in both directions—no imbalance pushing or pulling.

- Better Stability: Dual rods reduce piston rotation and bending moments, increasing precision, especially in high-speed or high-load scenarios.

- Higher Load Capacity: Distributing load evenly lessens wear and tear.

| Feature | Double Rod Cylinder | Single Rod Cylinder |

|---|---|---|

| Force Direction | Balanced in push/pull | Unbalanced, single side |

| Piston Stability | High — reduced rotation | Lower — can pivot or bend |

| Load Capacity | Higher due to dual rods | Limited |

| Structural Rigidity | Stronger, less vibration | Less stable under side loads |

Isn’t it fascinating how a seemingly small design tweak can bring so many performance perks? Now, what do you think could happen to machine accuracy if the piston gets unstable? How critical might this be for your line?

Key Advantages of Double Rod Cylinders

Let’s jump into the top benefits that make these cylinders a go-to in industrial automation:

- Symmetrical Push-Pull Force: The dual rods create equal forces on both ends. This balance stabilizes movement and avoids the twisting seen in single-rod cylinders.

- Enhanced Durability: Reduced bending lowers wear, extending the service life of the cylinder and connected components.

- Improved Precision: Dual rods reduce lateral play, achieving non-rotating accuracy often within ±0.1°.

- Increased Load Capacity: Distributing forces on two rods lets the cylinder handle heavier or more demanding loads.

- Versatile Mounting and Integration: Multiple cylinder sizes, strokes, and bearing types allow for easy customization.

- Compatibility with Sensors: Automated systems can integrate position sensors, boosting control capabilities.

| Advantage | Effect on Machinery |

|---|---|

| Force Balance | Stable, smooth motion |

| Durability | Longer equipment uptime |

| Precision | Higher accuracy in positioning |

| Load Handling | Supports heavier workloads |

| Mounting Flexibility | Suits diverse machinery designs |

| Sensor Integration | Enables smart automation systems |

If you want help selecting the right model, let me know — we can walk through specs based on your load, stroke, and environment.

Common Applications of Double Rod Cylinders

Now, where do these robust cylinders shine the most? Here are practical application areas:

- Automated Assembly Lines: Used in precise pick-and-place mechanisms and part positioning machines.

- Robotics: Ideal for controlled, balanced movement in robotic arms and grippers.

- Material Handling: For pushing, lifting, or clamping heavy items without distortion.

- Packaging Equipment: Accurate repeatable strokes needed in filling and sealing.

- Conveyors and Transporters: Double Rod Cylinders help with consistent push/pull actions.

- Specialized Sectors: Aerospace manufacturing, automotive production, medical device assembly.

| Industry | Application Example |

|---|---|

| Manufacturing | Precision piston positioning on assembly lines |

| Robotics | Balanced motion in robotic grippers |

| Logistics | Heavy load transport and clamping |

| Packaging | Accurate repetitive packaging cycles |

| Medical Equipment | High precision displacement for devices |

Curious about specific models? Feel free to ask for recommendations tailored to your workflow.

Discover how Double Rod Cylinders boost your machine’s precision and durability. Contact us today for expert guidance and tailored solutions!

Important Considerations When Choosing a Double Rod Cylinder

Picking the perfect Double Rod Cylinder isn’t just about size or power — here’s what else to keep in mind:

- Load and Stroke Requirements: Know your machinery’s force and travel distance needs.

- Operating Environment: Temperature, humidity, exposure to dust or chemicals influence material choices.

- Bearing Type: Options like ball bushing or slide bearing affect friction and precision.

- Mounting Configuration: Select from top, bottom, or rear mounting to fit your design.

- Integration Needs: Compatibility with sensors or cushioning to optimize automation.

| Factor | Impact | Tips for Selection |

|---|---|---|

| Load Capacity | Ensures durability and performance | Slightly oversize for safety margin |

| Stroke Length | Defines movement range | Match exactly for machine specs |

| Environment | Prevents premature wear | Choose corrosion-resistant materials |

| Bearing Type | Affects smoothness and lifespan | Match to speed and load demands |

| Mounting Type | Influences ease of installation | Confirm space and orientation |

| Automation Fit | Sensor compatibility and smart control | Plan for future upgrades |

Double Rod Cylinders are the unsung heroes behind many precise, heavy-duty industrial tasks. With their balanced force, enhanced durability, and exceptional stability, these cylinders improve machine accuracy and reliability while reducing maintenance costs. Their versatility across numerous applications—from robotics to packaging—makes them an invaluable choice for modern automation.

Whether you’re upgrading existing equipment or designing new machinery, considering a Double Rod Cylinder could save you headaches and boost your production efficiency. Curious to explore specific models and configurations? Reach out to discover options tailored for your business needs!

FAQ

What distinguishes a Double Rod Cylinder from a Single Rod Cylinder?

Double Rod Cylinders feature rods on both ends of the piston, delivering balanced forces and superior stability, unlike single rods, which create asymmetric forces and potential bending.

Can Double Rod Cylinders be used for lifting heavy loads?

Absolutely. Their balanced design allows them to handle heavier and more dynamic loads effectively.

Are Double Rod Cylinders difficult to maintain?

Not at all. Their design reduces wear, but routine inspections of seals and bearings ensure longevity.

How do I select the right Double Rod Cylinder for my needs?

Consider your force, stroke, environment, and mounting needs. We can help you narrow down the options.

Do Double Rod Cylinders support automation features?

Yes, many models support integration with position sensors and other smart automation components.