Are you looking for steady, precise motion in your machinery? Double rod cylinder might just be your best friends in this quest. Whether you’re updating equipment or planning a new installation, understanding how to select the right double rod cylinder is crucial. Let’s dive deep into this topic and make the selection process straightforward and effective.

What is a Double Rod Cylinder?

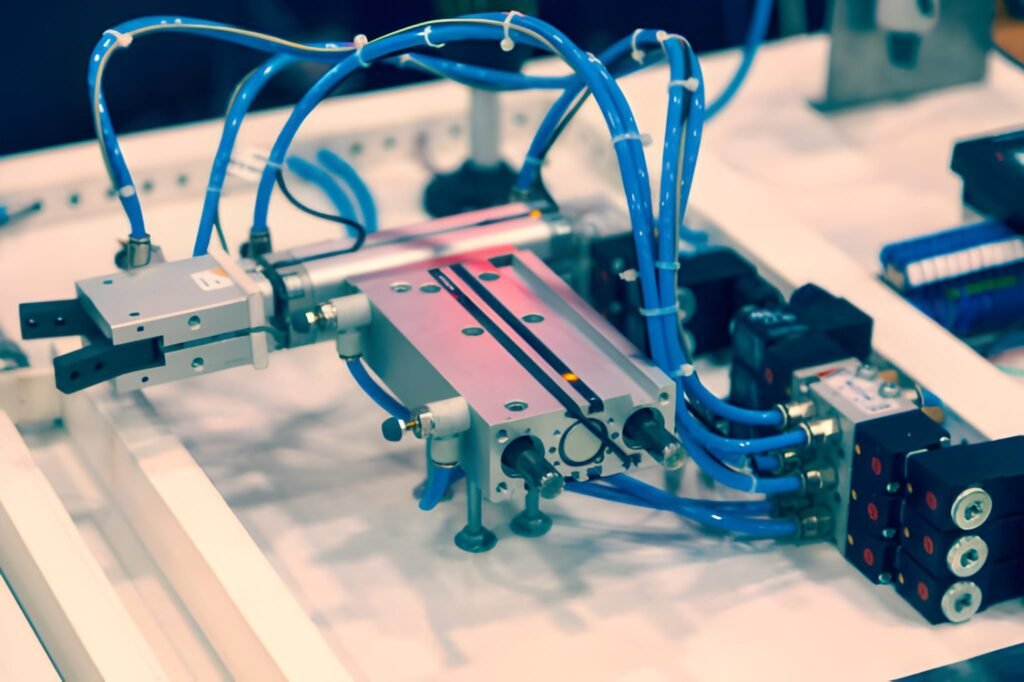

A CXSM double rod cylinder is a type of pneumatic or hydraulic actuator with a unique design: it has rods protruding from both ends of the cylinder. Imagine a piston in the middle with two rods coming out opposite sides—this design allows forces to be applied and controlled equally on both ends.

| Feature | Description |

|---|---|

| Structure | Two rods extending from either side of the piston |

| Motion | Symmetrical force and speed in both directions |

| Mounting flexibility | Can be mounted from multiple sides, enabling versatile installation |

This symmetry ensures balanced operation, reducing bending and improving control. It’s perfect for tasks needing precise positioning and equal force in push and pull.

Fun fact: The design also helps reduce wear since the forces don’t cause uneven stresses!

Key Parameters for Selecting a Double Rod Cylinder

Before jumping into purchases, check these crucial factors:

| Parameter | Considerations & Tips |

|---|---|

| Bore and Rod Diameter | Must match the load requirements; bore size dictates force capacity, rod diameter affects strength and stiffness |

| Stroke Length | How far does the cylinder need to move? Longer strokes offer more reach but might limit speed |

| Materials & Sealing | Environment matters! Choose corrosion-resistant materials if exposed to moisture or chemicals; seals affect durability |

| Mounting Style | Options include flange, ear mount, or foot mount—choose based on machinery design |

Selecting improper sizes or materials can cause premature failure or inefficient operation. Need help sizing? I can guide you through some simple load and force calculations!

Application Scenarios and Their Impact on Selection

Different industries and machines demand different features in their cylinders.

| Industry/Application | Why Double Rod Cylinders Excel |

|---|---|

| Industrial Automation | Requires smooth, precise, and repetitive motion; double rod cylinders provide exact positioning |

| Material Handling | Offers balanced push-pull forces for stable lifting and positioning |

| Robotics | Enables highly controllable and programmable motion in both directions |

| Harsh Environments | Specialized materials and seals can resist high temperatures, dust, or corrosive chemicals |

Is your application unique? Many manufacturers offer custom options — let’s chat about your needs!

Performance Factors That Make a Difference

A great double rod cylinder isn’t just about size. Here are some performance details to keep in mind:

- Force and Speed: Ensure the cylinder can provide enough force for both push and pull strokes.

- Cushioning: Look for designs with good air cushions or shock absorbers to protect your machinery.

- Durability: Steel or aluminum bodies with quality seals extend cylinder lifetime.

- Precision: Balanced rods prevent bending and allow for precise movement control.

| Feature | Impact on Operation |

|---|---|

| Balanced Forces | Reduces wear and unwanted vibrations |

| Air Cushioning | Softens piston stops, lowering impact |

| High-quality Seals | Prevents leaks, extends maintenance intervals |

Would you like detailed specs or comparisons of leading cylinders? I can help you decode technical datasheets!

Discover how Double Rod Cylinder boost your machine’s precision and durability. Contact us today for expert guidance and tailored solutions!

Maintenance Tips for Longer Cylinder Life

Taking care of your double rod cylinder pays off.

- Regular Inspection: Check for leaks, rod straightness, and seal condition.

- Keep it Clean: Dust and debris can damage seals and rods.

- Lubricate according to manufacturer guidelines.

- Monitor Operation: Notice unusual noises or sluggishness early.

| Tip | Benefits |

|---|---|

| Clean Environment | Prevents premature wear |

| Scheduled Lubrication | Ensures smooth, long-lasting motion |

| Timely Seal Replacement | Avoids costly leaks and downtime |

Got a specific maintenance challenge? Let’s troubleshoot it together!

How to Choose the Right Supplier

Choosing who you buy your double rod cylinder from is almost as important as choosing the cylinder itself.

Look for:

- Proven Quality: Certifications and industry standards matter.

- Customization Options: Can they tailor the cylinder to your needs?

- Customer Support: Quick, knowledgeable help saves time.

- Competitive Pricing: Balance cost with quality; cheapest is not always best.

Table comparing supplier features:

| Feature | Why It Matters |

|---|---|

| Certifications | Guarantees safety and reliability |

| Customization | Fits cylinders exactly to application |

| Support Availability | Reduces downtime and errors |

Ready to source a double rod cylinder? Contact us today for expert guidance and competitive quotes!

Double rod cylinder are a versatile, reliable choice for industrial applications needing equal push-pull force and precise control. By choosing the right size, material, and supplier, you ensure smooth operation and long equipment life. Whether automating, lifting, or building robotics, these cylinders will keep your systems running strong.

Feel free to reach out with your requirements, and we will help tailor the perfect double rod cylinder solution for your business. Ready to enhance your industrial efficiency? Let’s get started today!

FAQ

What are the main advantages of double rod cylinders?

Balanced force, higher precision, and durability.

How to calculate the required bore size?

Based on load and operating pressure; I can help with formulas.

Can they be customized?

Yes, manufacturers often provide tailored specifications.

Are they expensive?

Slightly more than single rod, but the performance justifies it.

What mounting types can be used?

Flange, foot mount, ear mount, and others depending on design.

How long do they last?

With proper care, many years under favorable conditions.