The FRC Series FRL Unit is designed for precise air preparation in pneumatic automation applications. It filters out contaminants such as dust, oil, and water droplets to prevent equipment damage. The pressure regulator maintains a consistent output pressure despite upstream fluctuations, while the lubricator accurately injects oil mist into the air flow to reduce internal wear of moving components. Made with durable zinc alloy housing to reduce leakage and capable of handling maximum pressures up to 1.6 MPa, the unit offers reliable operation in industrial environments ranging from 5°C to 60°C.

Main Features and Advantages

High Maximum Pressure: Supports outlet pressure up to 1.2 MPa and max working pressure of 1.6 MPa for demanding pneumatic systems.

Durable Construction: Zinc alloy body with improved density and leak resistance compared to aluminum alloy models.

Automatic Oil Filling: Lubricator can be refilled without stopping operation, supporting continuous system function.

Filter Precision: Standard 40 μm filter element with option for 5 μm for high-clean air demands.

Drain Options: Available with manual or auto drain variants for condensate removal to reduce maintenance.

Compact Size: Mini to mid-size models suitable for space-constrained system installations.

Versatile Port Sizes: Multiple Rc(G) port sizes (1/8″, 1/4″, 3/8″, 1/2″) to match common pneumatic pipelines.

Detailed Applications

Automation Systems: Protect pneumatic actuators, cylinders, and valves in industrial robots and conveyor systems.

Manufacturing: Providing clean and regulated air supply for pneumatic tools and machine operations in assembly lines.

Packaging & Material Handling: Enhances reliability of air-driven packaging machines and conveyors.

Electronics and Food Industry: Ensures contaminant-free and lubricated air for sensitive pneumatic instrumentation.

General Pneumatic Equipment: Suitable for any compressed air system requiring consistent filtration, pressure control, and lubrication.

| General technical data | ||||||||||

| Size | Mini | Midi | Maxi | |||||||

| Pneumatic connection 1, 21) | G1/8,G1/4,G3/8 | G1/4,G3/8,G1/2,G3/4 | G1/2,G3/4,G1 | |||||||

| Design | Filter regulator with/without pressure gauge | |||||||||

| Proportional standard mist lubricator | ||||||||||

| Type of mounting | Via accessories | |||||||||

| In-line installation | ||||||||||

| Mounting position | Vertical +5° | |||||||||

| Grade of filtration | {um} | 5 | ||||||||

| 40 | ||||||||||

| Bowl guard | Metal bowl guard | |||||||||

| Condensate drain | Manual, rotary | |||||||||

| Fully automatic | ||||||||||

| Actuator lock | Rotary knob with latch | |||||||||

| Rotary knob with integrated lock | ||||||||||

| Pressure regulation range | {bar} | 0.5 … 7 | ||||||||

| 0.5 … 12 | ||||||||||

| Max. pressure hysteresis | {bar} | 0.2 | 0.4 | |||||||

| Pressure indication | With pressure gauge | |||||||||

| Prepared for G1/8 | Prepared for G1/4 | Prepared for G1/4 | ||||||||

| Max. condensate volume | {cm3} | 22 | 43 | 802) | ||||||

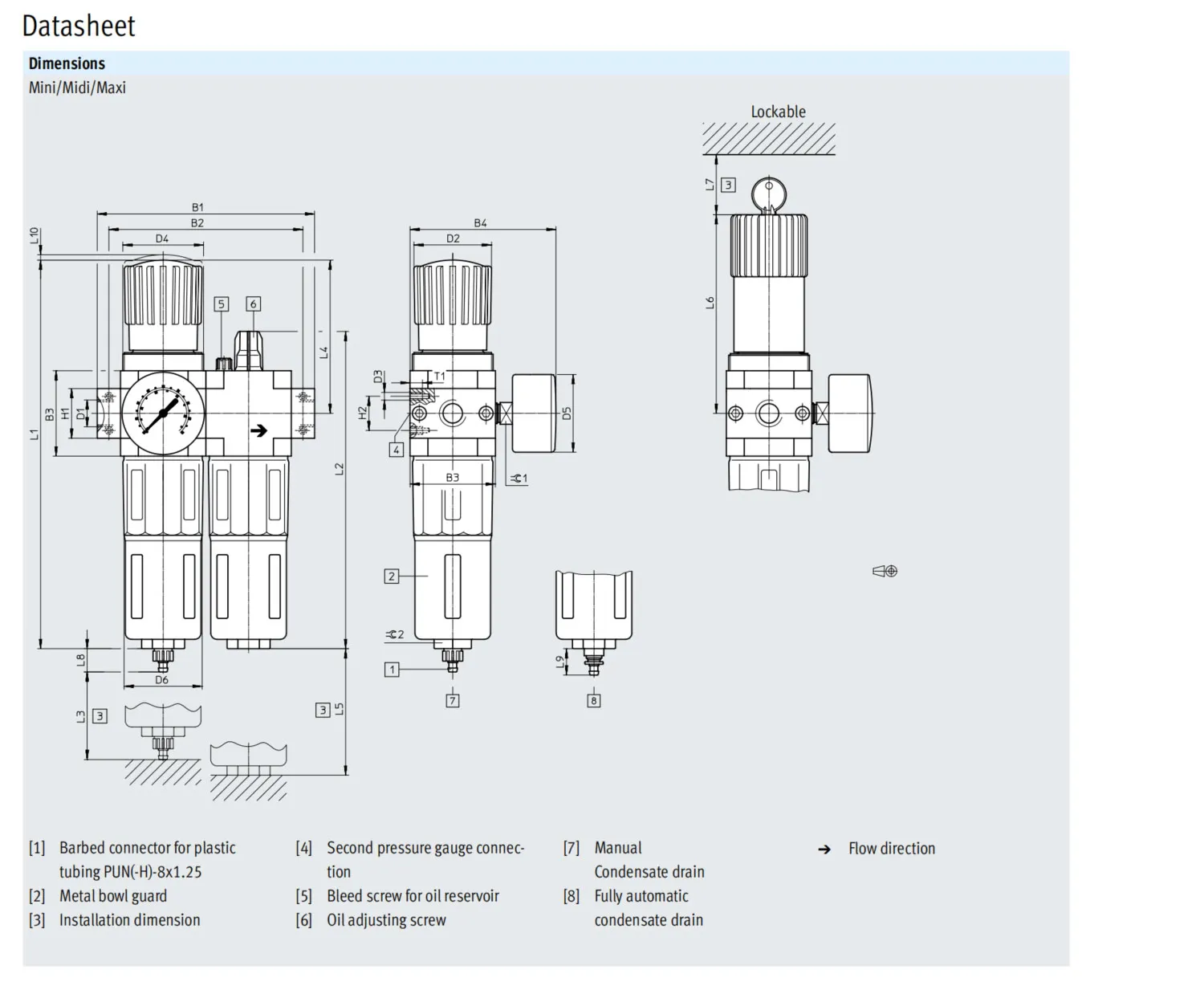

| Type | B1 | B2 | B3 | B4 | D1 | D2 ∅ | D3 | D4 ∅ | D5 | D6 ∅ |

| Mini | ||||||||||

| FRC-1/8-D-MINI | 104 | 92 | 40 | 76 | G1/8 | 31 | M4 | M36X1.5 | 39 | 38 |

| FRC-1/4-D-MINI | G1/4 | |||||||||

| FRC-3/8-D-MINI | 110 | G3/8 | ||||||||

| Midi | ||||||||||

| FRC-1/4-D-MIDI | 140 | 125 | 55 | 95 | G1/4 | 50 | M5 | M52X1.5 | 39 | 52 |

| FRC-3/8-D-MIDI | G3/8 | |||||||||

| FRC-1/2-D-MIDI | G1/2 | |||||||||

| FRC-3/4-D-MIDI | G3/4 | |||||||||

| Maxi | ||||||||||

| FRC-1/2-D-MAXI | 162 | 146 | 66 | 106 | G1/2 | 31 | M5 | M36X1.5 | 39 | 65 |

| FRC-3/4-D-MAXI | 106 | G3/4 | 31 | M36X1.5 | ||||||

| FRC-1-D-MAXI | 182 | 157 | 106 | G1 | 31 | M36X1.5 | ||||

| Type | H1 | H2 | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | T1 | 1 | 2 |

| Mini | |||||||||||||||

| FRC-1/8-D-MINI | 20 | 11 | 193 | 169 | 60 | 69 | 100 | 98 | 60 | 15 | 19 | 3 | 7 | 14 | 22 |

| FRC-1/4-D-MINI | |||||||||||||||

| FRC-3/8-D-MINI | |||||||||||||||

| Midi | |||||||||||||||

| FRC-1/4-D-MIDI | 32 | 22 | 250 | 204 | 80 | 99 | 120 | 130 | 60 | 15 | 19 | 3 | 8 | 14 | 24 |

| FRC-3/8-D-MIDI | |||||||||||||||

| FRC-1/2-D-MIDI | |||||||||||||||

| FRC-3/4-D-MIDI | |||||||||||||||

| Maxi | |||||||||||||||

| FRC-1/2-D-MAXI | 32 | 22 | 252 | 228 | 90 | 82 | 150 | 111 | 60 | 15 | 19 | 3 | 8 | 14 | 24 |

| FRC-3/4-D-MAXI | 32 | 252 | 82 | 111 | |||||||||||

| FRC-1-D-MAXI | 40 | 252 | 82 | 111 | |||||||||||

Installation Steps and Maintenance

Installation: Follow airflow direction marks; mount unit near pneumatic tools or valves ensuring easy access for maintenance. Use appropriate fittings compatible with Rc or G pipe threads.

Filter Maintenance: Visually inspect the bowl for accumulated condensate or dirt; replace filter elements regularly (every 3-6 months). For heavy moisture environments, consider auto drain versions.

Pressure Regulation: Adjust the regulator knob to set the desired output pressure; lock knob to prevent accidental changes if available.

Lubricator Care: Maintain oil level and use recommended turbine oils (ISO VG32). Adjust lubrication drop rate as per tool requirements, typically 1-12 drops per 1000L air. Lubricator supports refill without system shutdown.

Routine Checks: Monitor for air leaks, pressure stability, and cleanliness of air supply periodically to prevent performance degradation.

How to Choose the Right FRC Series FRL Unit

Flow Rate: Determine your pneumatic system’s maximum air consumption in L/min (ANR) or SCFM and select a unit with sufficient flow capacity.

Operating Pressure: Select a unit that supports the compressor’s maximum pressure output and allows regulation to the tool’s required range (up to 1.6 MPa max).

Filter Grade: Choose between 40 μm standard filters or 5 μm filters for cleaner air based on application needs.

Port Size: Match the FRL unit ports (Rc1/8, Rc1/4, Rc3/8, Rc1/2) to your air piping system to minimize pressure loss.

Drain Type: For high moisture environments, prefer auto-drain versions to avoid manual condensate removal.

Lubrication Requirements: Ensure lubricator oil type and refill method fit your pneumatic tool’s lubrication needs.

Request a Quote Now

Our team will get back to you within 24 hours.