The AC.BC Series FRL Unit serves as an essential air preparation module for automated pneumatic systems, effectively filtering out impurities like dust, water, and oil aerosols, regulating pressure within desired limits, and supplying lubricating oil mist for moving components. Built with corrosion-resistant materials and offering a modular design, this unit guarantees dependable air quality and performance stability, supporting a max working pressure of up to 1.0 MPa and a temperature range typically from 5°C to 60°C.

Main Features and Advantages

Compact & Delicate Structure: Designed for convenient installation in tight spaces typical of automation setups.

High-Efficiency Filtration: Standard 40 μm filter element with optional 5 μm precision captures fine particulates and moisture.

Stable Pressure Control: Self-locking mechanism prevents pressure drift caused by external interference, maintaining consistent output pressure.

Visible Lubrication Control: Transparent dome allows direct observation of oil droplet rate for precise lubrication management.

Low Pressure Loss & High Water Separation: Ensures minimal airflow restriction while effectively removing moisture from compressed air.

Robust Materials: Aluminum alloy body with PC bowl and metal guards (on certain models) ensuring durability and resistance to harsh environments.

Detailed Applications

Automation Systems: Ideal for robotic controls, conveyor systems, and assembly line pneumatic tools requiring consistent air quality and pressure stability.

Manufacturing Industry: Suitable for industrial tool air supply, machine operation, and pneumatic actuators in production environments.

Packaging & Food Processing: Ensures hygienic air condition and proper lubrication without contamination, meeting food safety standards.

Electronics & Pharmaceuticals: Maintains sensitive pneumatic instruments with finely regulated and filtered air.

General Pneumatic Equipment: Enhances performance and durability across a broad range of uncritical to moderate industrial pneumatic applications.

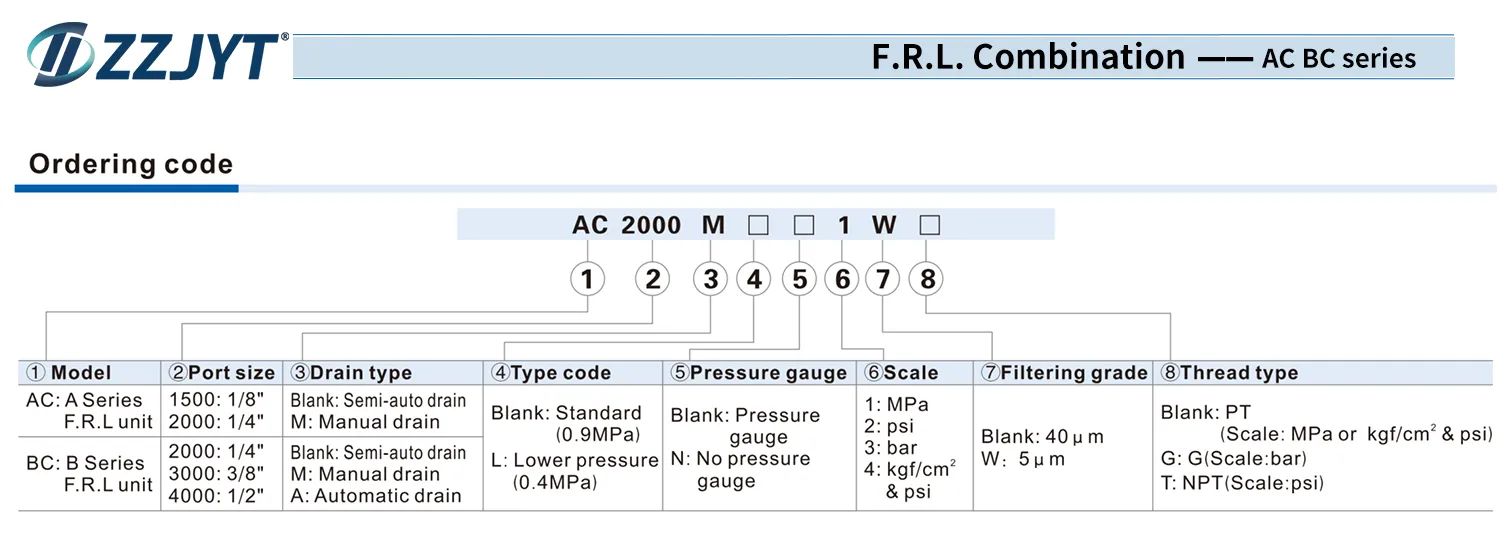

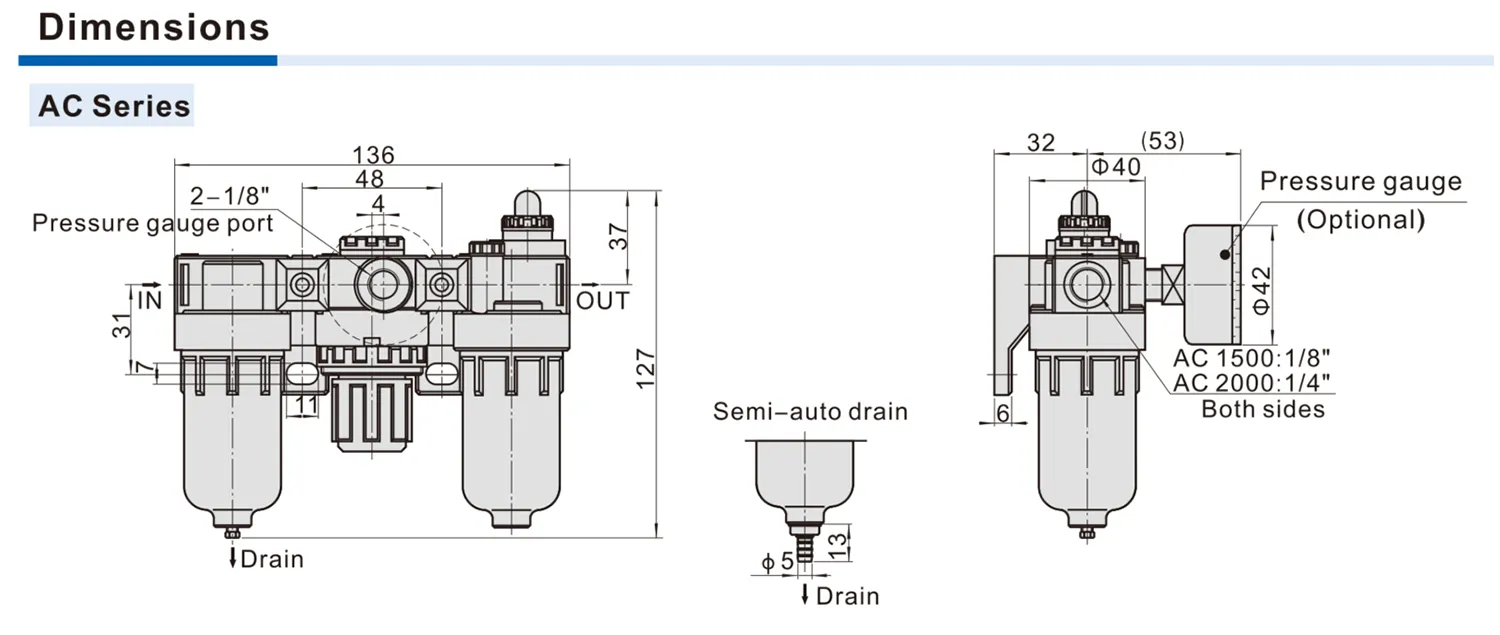

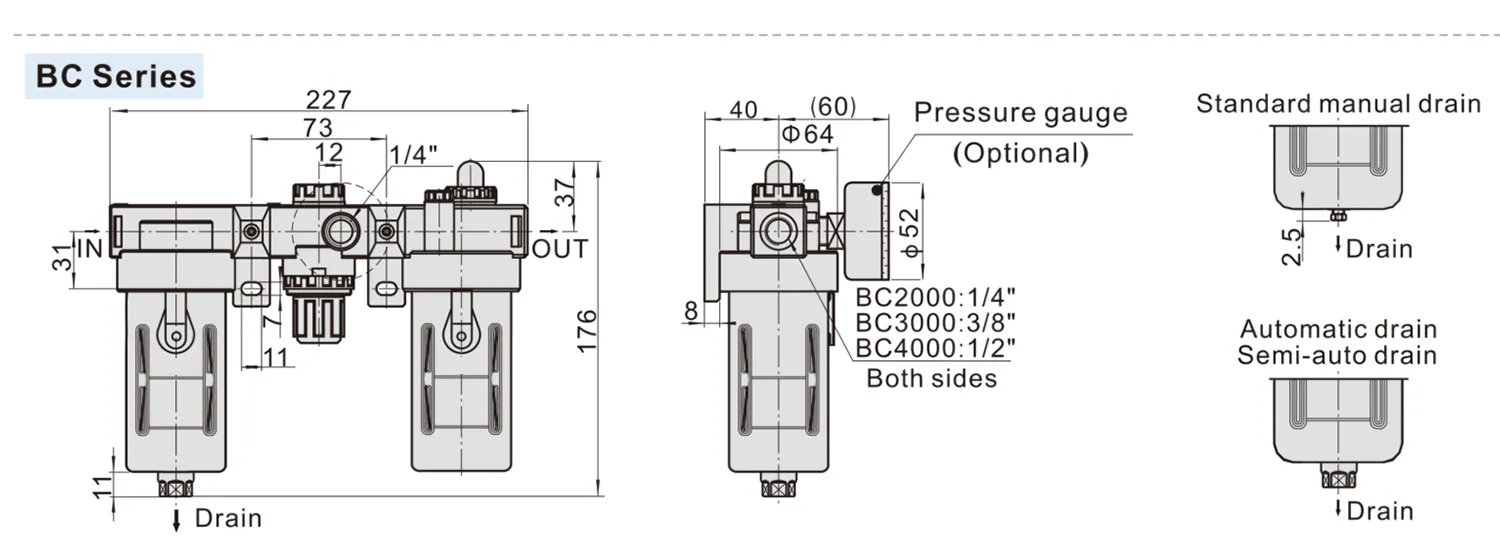

| Modal | AC1500 | AC2000 | BC2000 | BC3000 | BC4000 | |

| Fluid | Air | |||||

| Port size | 1/8″ | 1/4″ | 1/4″ | 3/8″ | 1/2″ | |

| Filtering grade | 40 μ m or 5 μ m | |||||

| Pressure range | Semi-auto and automatic drain:0.15~0.9Mpa(20~130Psi) Manual drain:0.05~0.9Mpa(7~130Psi) | |||||

| Max.pressure | 1.0Mpa(145Psi) | |||||

| Proof pressure | 1.5Mpa(215Psi) | |||||

| Temperature range | -5~70℃(unfreeze) | |||||

| Capacity of drain bowl | 15CC | 60CC | ||||

| Capacity of oil bowl | 25CC | 90CC | ||||

| Recommended lubricant | ISO VG 32 or equivalent | |||||

| Constitute | Filter | AF1500 | AF2000 | BF2000 | BF3000 | BF4000 |

| Regulator | AR1500 | AR2000 | BR2000 | BR3000 | BR4000 | |

| Lubricator | AL1500 | AL2000 | BL2000 | BL3000 | BL4000 | |

Installation Steps and Maintenance

Installation: Align unit following the airflow direction marked by arrows; mount securely using brackets as necessary. Recommended to install upstream of pneumatic tools.

Filter Maintenance: Inspect the filter bowl weekly for contaminants; replace filter elements every 3 to 6 months depending on air quality. For humid conditions, automatic drain options reduce manual maintenance needs.

Regulator Check: Adjust pressure as needed and regularly inspect for stability; ensure self-locking knobs are secure to avoid accidental changes.

Lubricator Refill: Maintain oil levels regularly (every 2-4 weeks depending on usage) using turbine grade lubricating oil (ISOVG32 recommended). Monitor oil drip rate visually to avoid under- or over-lubrication.

Routine Inspections: Conduct periodic visual and functional checks for leaks, corrosion, or unusual noises to prevent unexpected downtime.

How to Choose the Right AC.BC Series FRL Unit

Airflow Capacity: Calculate your system’s max air flow requirement in L/min or CFM, and select a compatible model (e.g., BC2000, BC3000, BC4000) that meets or exceeds that flow.

Pressure Requirements: Ensure maximum working pressure (typically up to 1.0 MPa) and adjustable pressure range align with your pneumatic system needs.

Connection Size: Match the unit’s port size (1/4″, 3/8″, 1/2″) to your existing pipeline to avoid pressure losses.

Filter Precision: Choose standard 40 μm for general use; opt for 5 μm filtration for higher purity requirements.

Environmental Adaptability: For humid or corrosive conditions, prefer AC.BC series models with corrosion resistance, automatic drains, and metal bowl guards for longevity.

Application Specifics: Determine if your system requires all three functions (filter, regulator, lubricator) or a simpler combination to optimize cost and performance.

Request a Quote Now

Our team will get back to you within 24 hours.