The control method of VT307 solenoid valve is as follows:

1. Electrical control:

Connect power supply: Connect the power supply correctly according to the rated voltage requirements of the solenoid valve. Common voltage types include 12V DC, 24V AC, and 220V AC. Ensure the stability and reliability of the power supply, and avoid damage to the solenoid valve caused by excessive voltage fluctuations.

Control signal input: Send control signals to solenoid valves through control systems such as PLC, relays, etc. When the control signal reaches the solenoid coil of the solenoid valve, a magnetic field is generated, causing the valve core to move.

2. In terms of fluid control:

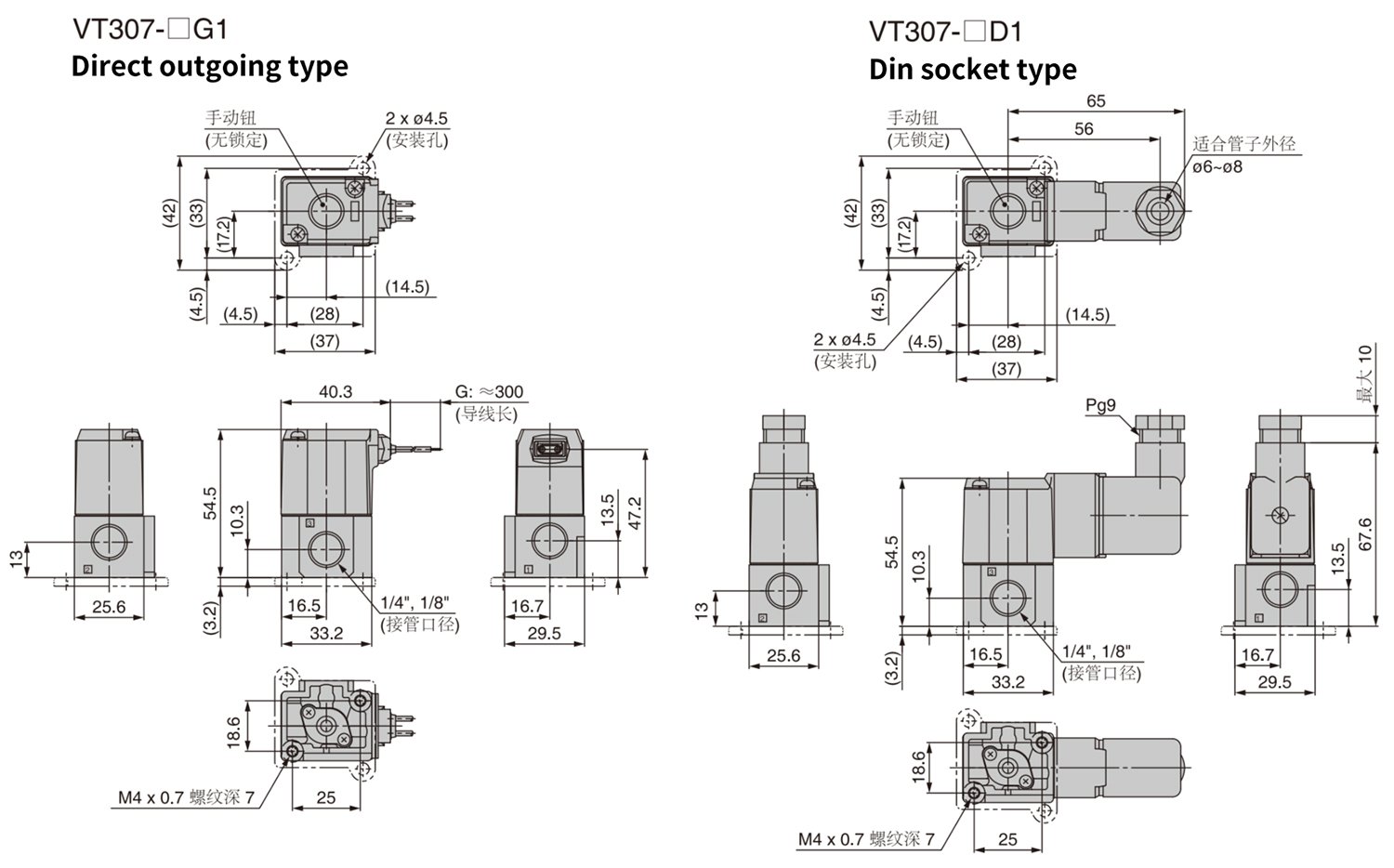

Installation and takeover: Install the solenoid valve correctly and firmly connect the fluid pipeline to the interface of the solenoid valve. Note that the direction of fluid flow should be consistent with the arrow markings on the solenoid valve, otherwise it may cause the solenoid valve to malfunction or be damaged.

Pressure and temperature control: Ensure that the pressure and temperature of the fluid are within the allowable range of the VT307 solenoid valve. If the fluid pressure is too high, it may exceed the bearing capacity of the solenoid valve and affect its service life; If the temperature is too high or too low, it may affect the sealing performance and working efficiency of the solenoid valve.

Specifications

| Fluid used: Air |

| Zero position state: normally on or normally off universal |

| Environment and fluid temperature: -10~50 ℃ (unfrozen) |

| Response time: 20ms or less (0.5MPa) |

| Maximum operating frequency: 10Hz |

| Lubrication: Do not |

| Manual operation: Non locking button type |

| Anti impact/vibration capability: 150/50m/s ² |

| Protection structure: dustproof |

Request a Quote Now

Our team will get back to you within 24 hours.