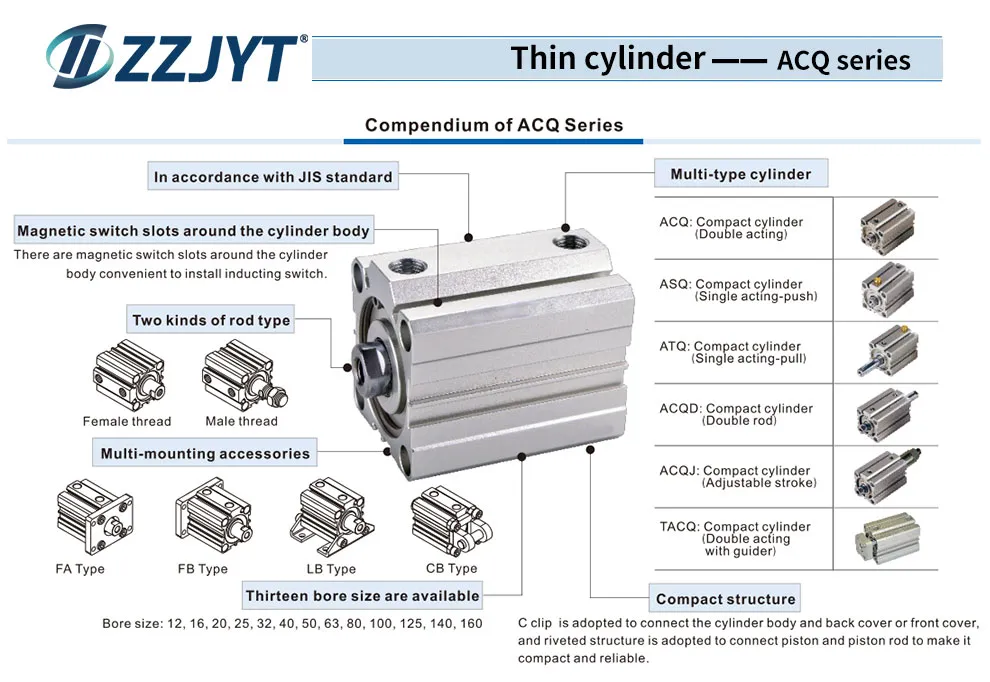

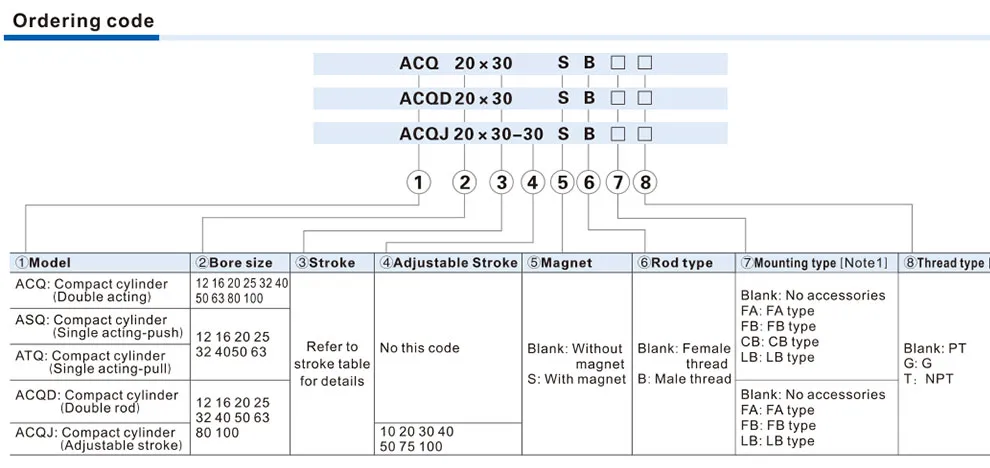

The ACQ Series miniature pneumatic cylinder is designed according to JIS standards, offering superior precision and ease of integration in automation systems. Constructed from hard-anodized aluminum alloy, this compact cylinder is corrosion-resistant and lightweight, suitable for space-limited industrial and robotic applications. The magnetic piston within enables accurate position detection through magnetic sensors, facilitating smooth process control and automation feedback. With bore sizes ranging from 12mm to 100mm and multiple stroke options, the ACQ Series supports diverse tasks involving compact actuation and sensing reliability. Its thin-profile design and sensor mounting grooves allow easy installation of inductive switches, enhancing usability.

Key Features and Advantages

Magnetic Piston for Position Sensing: Enables integration of magnetic sensors for non-contact, accurate position feedback.

Compact and Lightweight Aluminum Alloy Body: Ideal for applications with stringent space and weight constraints.

JIS Standard Compliance: Ensures compatibility and easy replacement with other standard pneumatic systems.

Hard Anodized Surface: Provides corrosion resistance and long-term durability.

Wide Bore and Stroke Range: Bore sizes from 12mm up to 100mm with strokes tailored to diverse needs.

Integrated Sensor Mounting Grooves: Facilitate convenient installation of magnetic sensors without additional brackets.

Double Acting and Single Acting Options: Support versatile actuation requirements.

Efficient Cushioning: Rubber cushions absorb piston impact, reducing noise and wear.

Maintenance-Free Operation: Featuring sealing components designed for long service intervals and minimal upkeep.

Detailed Applications

Robotics: Accurate and compact actuation with position feedback for robotic arms and automated tools.

Automated Assembly Lines: Reliable cylinder with sensing for precise component positioning.

Medical Devices: Small footprint pneumatic actuation with non-contact sensing to maintain hygiene.

Semiconductor Manufacturing: High accuracy and clean operation required for sensitive processes.

Packaging Machinery: Smooth and reliable motion with sensor feedback for automated packing systems.

Electronics Production: Supports small-scale automation with space-efficient design.

General Industrial Automation: Suitable for various compact automated systems requiring position monitoring.

| Bore size(mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| Acting type | Double acting | ||||||||||

| Single acting_Push type、Single acting_Pull type | – | ||||||||||

| Fluid | Air (to be filtered by 40 u m filter element) | ||||||||||

| Operating pressure | Double acting | 0.15-1.0MPa(22-145psi)(1.5-10.0bar) | |||||||||

| Single acting | 0.2-1.0MPa(28-145psi)(2.0-10.0bar) | ||||||||||

| Proof pressure | 1.5MPa(215psil)(15bar) | ||||||||||

| Temperature℃ | -20-70℃ | ||||||||||

| Speed range mm/s | Double acting: 30~500 Single acting: 50~500 | ||||||||||

| Stroke tolerance | Stroke≤100⁺₀¹·⁰ Stroke>100⁺₀¹·⁵ | ||||||||||

| Cushion type | Bumper | ||||||||||

| Port size | M5*0,8 | 1/8″ | 1/4″ | 3/8″ | |||||||

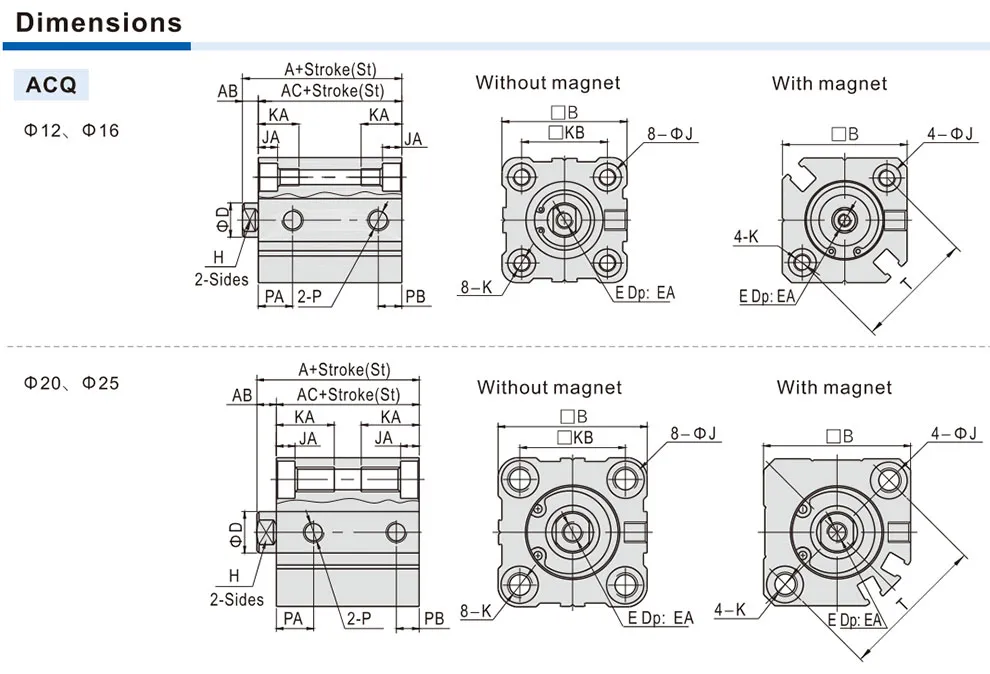

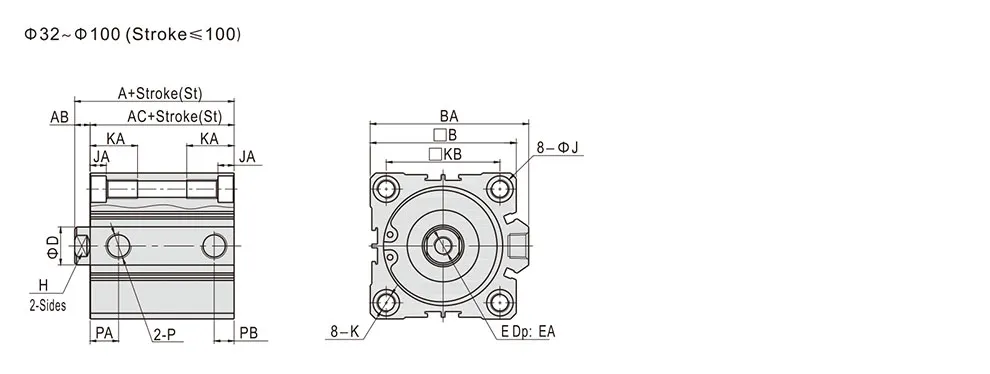

| Type | Without magnet | With magnet | AB | B | D | E | EA | H | J | JA | K | KA | KB | P | Without magnet | With magnet | T | ||||||||

| Bore sizeItem | A | AC | A | AC | PA | PB | PA | PB | |||||||||||||||||

| Stroke | St≤50 | St=55 | St≥60 | St≤50 | St=55 | St≥60 | |||||||||||||||||||

| 12 | 20.5 | – | – | 17 | – | – | 31.5 | 28 | 31.5 | 25 | 6 | M3*0.5 | 6 | 5 | 6 | 3.5 | M4*0.7 Thru.hole:3.4 | 11 | 15.5 | M5*0.8 | 7.5 | 5 | 9 | 7 | 22 |

| 16 | 22 | 22 | 22 | 18.5 | 18.5 | 18.5 | 34 | 30.5 | 34 | 29 | 8 | M4*0.7 | 8 | 6 | 6 | 3.5 | M4*0.7 Thru.hole:3.4 | 11 | 20 | M5*0.8 | 8 | 5.5 | 9.5 | 5.5 | 28 |

| 20 | 24 | – | 34 | 19.5 | – | 29.5 | 36 | 31.5 | 36 | 36 | 10 | M5*0.8 | 7 | 8 | 9 | 5.5 | M6*1.0 Thru.hole:5.2 | 17 | 25.5 | M5*0.8 | 9 | 5.5 | 9.5 | 5.5 | 36 |

| 25 | 27.5 | – | 37.5 | 22.5 | – | 32.5 | 37.5 | 32.5 | 37.5 | 40 | 12 | M6*1.0 | 12 | 10 | 9 | 5.5 | M6*1.0 Thru.hole:5.2 | 17 | 28 | M5*0.8 | 11 | 5.5 | 11 | 5.5 | 40 |

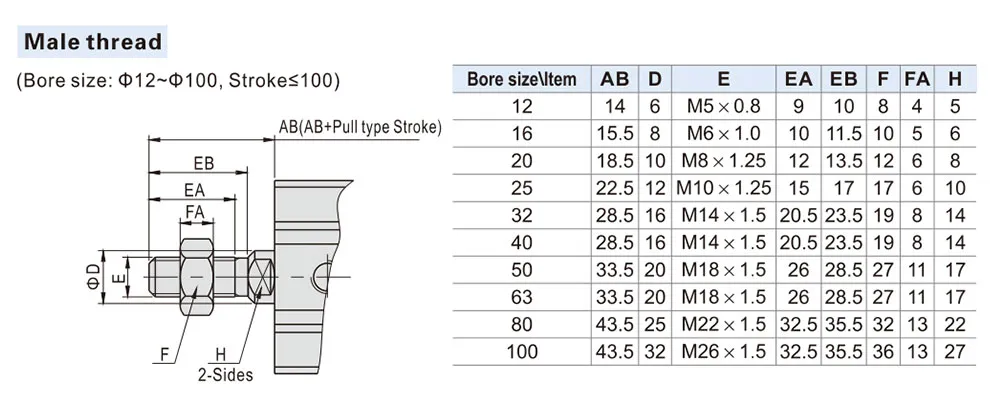

| Type | A(Without magnet) | A(With magnet) | AB | AC(Without magnet) | AC(With magnet) | B | BA | D | E | ||

| Bore sizeItem | St≤50 | St≥60 | St≤50 | St≥60 | |||||||

| 32 | 30 | 40 | 40 | 7 | 23 | 33 | 33 | 45 | 49.5 | 16 | M8X1.25 |

| 40 | 36.5 | 46.5 | 46.5 | 7 | 29.5 | 39.5 | 39.5 | 53 | 57 | 16 | M8X1.25 |

| 50 | 38.5 | 48.5 | 48.5 | 8 | 30.5 | 40.5 | 40.5 | 64 | 71 | 20 | M10X1.5 |

| 63 | 44 | 54 | 54 | 8 | 36 | 46 | 46 | 77 | 84 | 20 | M10X1.5 |

| 80 | 53.5 | 63.5 | 63.5 | 10 | 43.5 | 53.5 | 53.5 | 98 | 104 | 25 | M16X2.0 |

| 100 | 65 | 75 | 75 | 12 | 53 | 63 | 63 | 117 | 123.5 | 32 | M20X2.5 |

| Type | EA | H | J | JA | K | KA | KB | P | Without magnet | With magnet | |||

| Bore sizeItem | PA | PB | PA | PB | |||||||||

| 32 | St=5 | 13 | 14 | 9 | 5.5 | M6X1.0 Thru.hole:Φ5.2 | 17 | 34 | 1/8“ | 7.5 | 6.5 | 10.5 | 7.5 |

| St>5 | 10.5 | 7.5 | |||||||||||

| 40 | 13 | 14 | 9 | 5.5 | M6X1.0 Thru.hole:Φ5.2 | 17 | 40 | 1/8“ | 11 | 8 | 11 | 8 | |

| 50 | St=5 | 15 | 17 | 10.5 | 6.5 | M8X1.25 Thru.hole:Φ6.8 | 22 | 50 | 1/4“ | 9 | 9 | 10.5 | 10.5 |

| St>5 | 10.5 | 10.5 | |||||||||||

| 63 | St=5 | 15 | 17 | 14 | 9 | M10X1.5 Thru.hole:Φ8.5 | 28.5 | 60 | 1/4“ | 14 | 9.5 | 15 | 10.5 |

| St>5 | 15 | 10.5 | |||||||||||

| 80 | 20 | 22 | 17 | 11 | M12X1.75 Thru.hole:Φ10.3 | 35.5 | 77 | 3/8“ | 16 | 14 | 16 | 14 | |

| 100 | 26 | 27 | 17 | 11 | M12X1.75 Thru.hole:Φ10.3 | 35.5 | 94 | 3/8“ | 20 | 17.5 | 20 | 17.5 | |

Installation and Maintenance

Installation

Choose the suitable mounting brackets (foot, flange, clevis) based on machine design.

Connect air supply tubes ensuring clean, dry air is provided to extend seal life.

Mount magnetic sensors using the integrated grooves to ensure precise position detection.

Adjust cushioning valves to optimize piston deceleration and reduce shock.

Inspect all connections and perform leakage tests prior to operation.

Maintenance

Regularly check pneumatic connections and cylinder for wear or leaks.

Clean external surfaces and piston rods to maintain smooth operation.

Replace seals as needed based on operational hours and leakage signs.

Lubricate only if specified by manufacturer instructions during servicing.

Avoid excessive impact and operate within recommended pressure and temperature limits.

How to Select the Right ACQ Miniature Cylinder

Determine Bore Size and Stroke: Match to desired force output and linear travel.

Assess Sensing Requirements: Opt for magnetic piston models if position feedback is necessary.

Check Mounting Needs: Select compatible mounting accessories to fit your machine configuration.

Operating Environment: Aluminum alloy with anodizing suits many industrial conditions but consider environment specifics.

Actuation Type: Choose between double-acting or single-acting based on application demands.

Cushioning and Speed: Adjust according to load and cycle speed for optimal cylinder lifespan.

Request a Quote Now

Our team will get back to you within 24 hours.