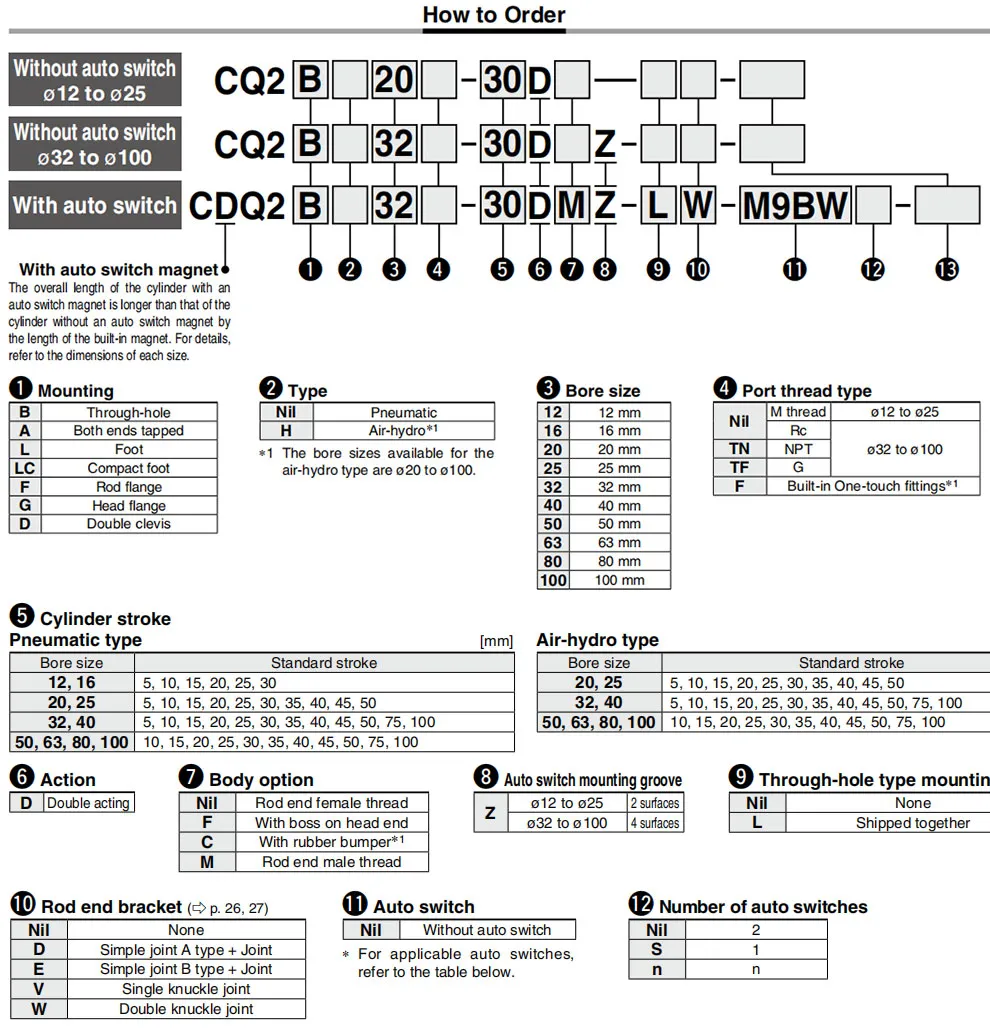

The CQ2 mini cylinder series offers a sophisticated balance of compact size, lightweight construction, and high performance tailored for tight or constrained spaces in industrial machinery. Constructed from strong aluminum alloy, the cylinder ensures long-lasting durability while minimizing machine weight. With bore sizes ranging from 4mm up to 200mm and flexible stroke options, CQ2 cylinders suit a variety of applications, from automated production lines to precision assembly. Its improved design incorporates integrated grooves for secure mounting of auto switches on multiple surfaces without the need for additional brackets, making installation faster and safer. This versatility combined with excellent durability and precision makes the CQ2 an ideal choice for modern compact automation solutions.

Key Features and Advantages

Compact and Lightweight Design: Aluminum alloy body reduces machine weight and fits easily in tight spaces.

Wide Bore and Stroke Range: Bore sizes from 4mm to 200mm with customizable stroke lengths adapt to diverse application needs.

Integrated Auto Switch Grooves: Auto switches can be mounted on up to four surfaces for flexible sensor positioning without extra brackets.

High Accuracy and Repeatability: Ensures precise linear actuation critical for space-limited machinery.

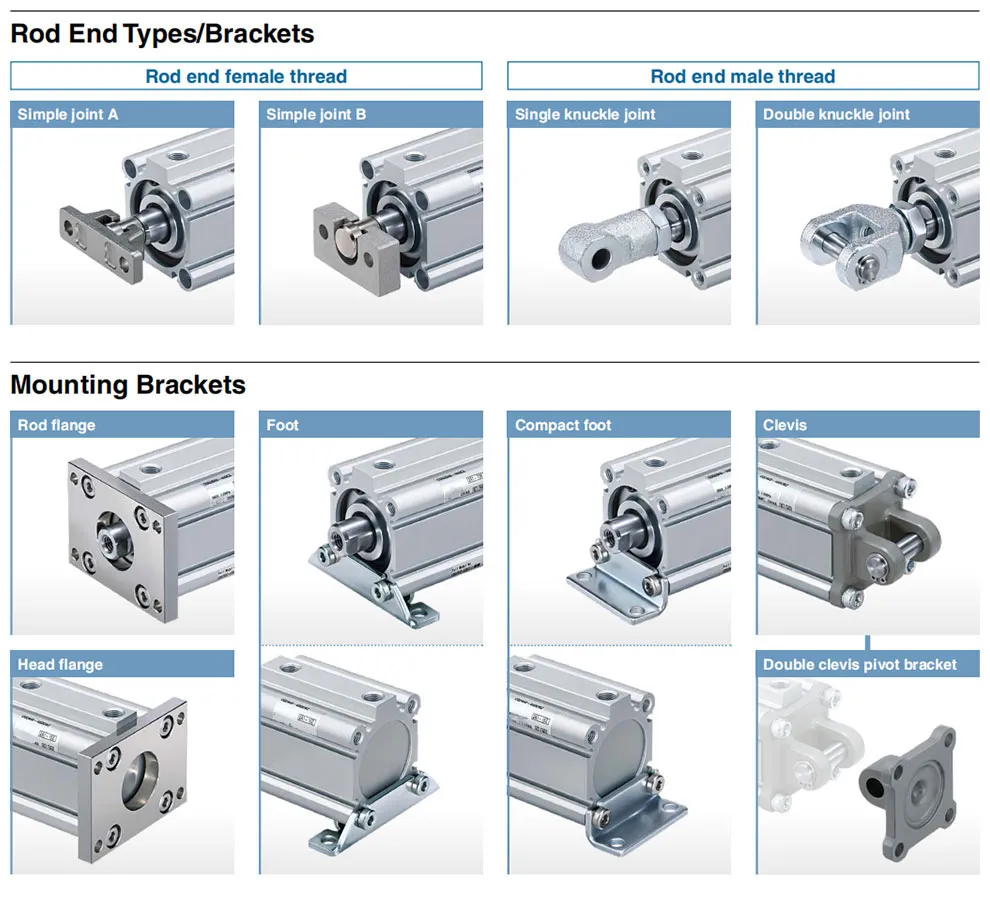

Multiple Mounting Options: Includes foot, flange, clevis, and pivot brackets to suit varying installation requirements.

Good Durability: High-quality seals and materials achieve long-term stable operation.

No Lubrication Required: Minimizes maintenance and maximizes operational efficiency.

Wide Operating Temperature Range: Suitable for environments from -10°C to 70°C (or up to 60°C with auto switches).

Adjustable Stroke Variants: Allow fine-tuned positioning tailored to machine dynamics.

Detailed Applications

The CQ2 mini cylinder is well-suited for:

Automated Assembly Equipment: Precise actuation in compact assembly lines.

Packaging Machinery: Efficient, space-saving pneumatic motion for packing and sorting.

Electronics Manufacturing: Small footprint cylinder ideal for PCB assembly and component handling.

Food and Beverage Automation: Hygienic and compact design suitable for clean environments.

Robotics: Actuators designed for handling and gripping where space is restricted.

Material Handling: Lightweight solutions enabling fast, repeatable linear motion.

General Industrial Automation: Flexible use in limited-space automated systems.

| Bore size(mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| Acting | Double acting, Single rod | ||||||||||

| Fluid | Air | ||||||||||

| Proof pressure | 1.5 Mpa | ||||||||||

| Maximum operating pressure | 1.0 Mpa | ||||||||||

| Minimum operating pressure | 0.07 Mpa | 0.05 Mpa | |||||||||

| Ambient and fluid temperatures | Without auto switch magnet: –10 to 70°C (No freezing) With auto switch magnet: –10 to 60°C | ||||||||||

| Lubrication | Not required (Non-lube) | ||||||||||

| Piston speed | 50~500 mm/s | ||||||||||

| Cushion | Without cushion or With rubber bumper | ||||||||||

| Allowable kinetic energy[J] | Without cushion | 0.022 | 0.038 | 0.055 | 0.09 | 0.15 | 0.26 | 0.46 | 0.77 | 1.36 | 2.27 |

| With rubber bumper | 0.043 | 0.075 | 0.11 | 0.18 | 0.29 | 0.52 | 0.91 | 1.54 | 2.71 | 4.54 | |

Installation and Maintenance

Installation

Determine the appropriate mounting method based on space constraints (foot mount, clevis, flange).

Utilize auto switch mounting grooves for secure, bracket-free sensor installation.

Connect pneumatic fittings ensuring clean, dry air supply and proper pressure settings.

Adjust stroke length as needed depending on the cylinder model.

Verify airtightness and smooth piston operation during initial testing.

Maintenance

Periodically inspect seals and pneumatic connections for wear or leaks.

Keep piston rod and cylinder body clean to prevent dust and debris buildup.

Re-lubricate only if recommended by manufacturer during seal replacement or overhaul.

Replace worn seals promptly to maintain performance.

Avoid impact or harsh environmental exposure beyond specified limits.

How to Select the Right CQ2 Mini Cylinder

Determine Bore Size: Match bore diameter to the required thrust force.

Select Stroke Length: Choose based on the required linear travel within available machine space.

Mounting Style: Foot, flange, clevis, or pivot mounts depending on machine design.

Check Auto Switch Compatibility: Use models with integrated switch grooves for optimal sensor placement.

Operating Environment: Select based on temperature range and any corrosion resistance needs.

Lubrication and Maintenance Needs: Consider models with no lubrication requirements for easier upkeep.

Request a Quote Now

Our team will get back to you within 24 hours.