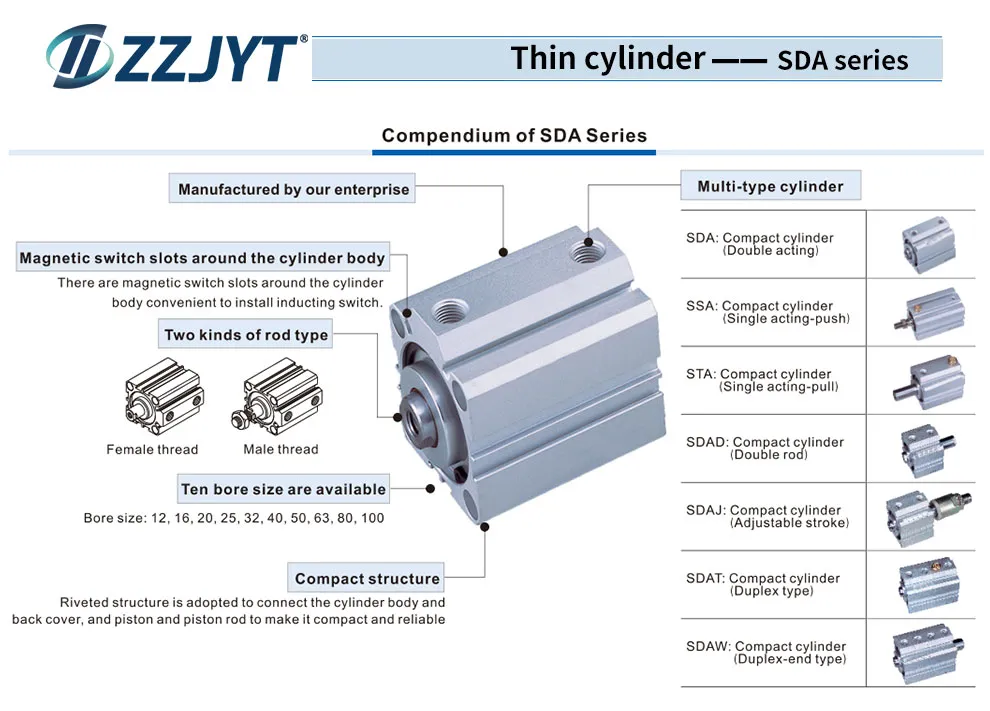

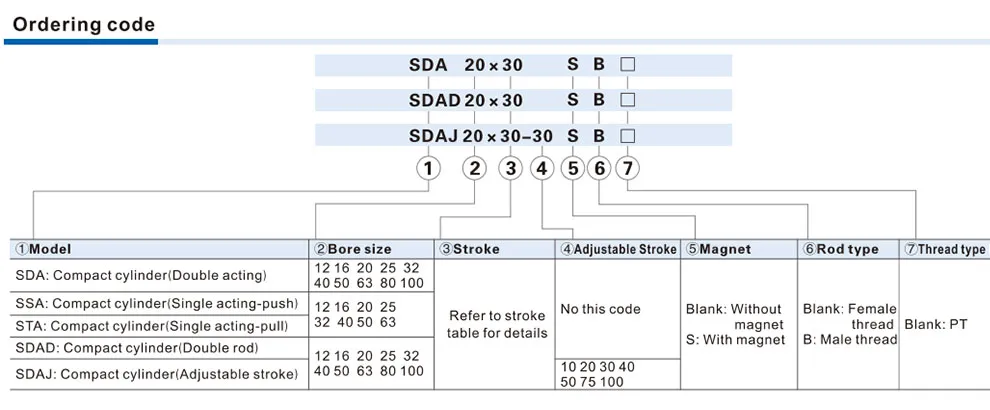

The SDA Series thin profile pneumatic actuator offers a compact size without compromising performance. Constructed from durable aluminum alloy with a hard anodized finish, the cylinder ensures excellent abrasion resistance and longevity. Its riveted design connects the cylinder body, end covers, piston, and rod, enhancing structural reliability while maintaining a slim form factor. Available in bore sizes from 12mm to 100mm and strokes from 5mm to 130mm, the SDA Series supports both double-acting and single-acting configurations. The integrated magnetic sensor grooves simplify sensor installation, allowing for reliable position detection in automated systems. With operating pressures up to 1.0 MPa and temperature tolerance between -20°C and 80°C, the SDA Series is suitable for a wide range of industrial automation tasks requiring compact pneumatic actuation.

Key Features and Advantages

Thin Profile and Compact Design: Saves valuable installation space in tight machinery layouts.

Lightweight Aluminum Alloy Body: Reduces machine weight and boosts efficiency without sacrificing strength.

Durable Riveted Construction: Offers high structural integrity and reliability during continuous operation.

Wide Bore and Stroke Options: Bore sizes between 12mm and 100mm with customizable strokes fit diverse automation needs.

Integrated Magnetic Sensor Slots: Facilitate easy and secure installation of inductive sensors without extra brackets.

Excellent Wear Resistance: Hard anodized cylinder barrel prevents abrasion and corrosion.

Single and Double Acting Models: Provide application flexibility for various pneumatic control systems.

High Operating Speed Range: Double acting: 30-500 mm/s; Single acting: 50-500 mm/s.

Wide Temperature Range: Operates reliably in environments from -20°C to 80°C.

Installation and Maintenance

Installation

Mount using recommended methods such as foot, flange, clevis, or pivot brackets suitable for your machine configuration.

Attach magnetic sensors within integrated grooves ensuring precise piston position feedback.

Connect pneumatic lines ensuring clean, dry compressed air to enhance seal longevity.

Check the airtightness of all fittings and verify smooth piston travel during initial startup.

Maintenance

Regularly inspect and clean the piston rod and external cylinder surface to prevent contamination.

Replace seals or wipers at signs of leakage or wear to maintain performance.

Lubricate internally if manufacturer guidelines specify; otherwise, operation is generally maintenance-free.

Avoid operating above specified temperature and pressure limits.

Ensure cushioning valves are appropriately set to avoid excessive piston impact.

| Bore size(mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| Acting type | Double acting | ||||||||||

| Single acting_Push type、Single acting_Pull type | – | ||||||||||

| Fluid | Air (to be filtered by 40 u m filter element) | ||||||||||

| Operating pressure | Double acting | 0.15-1.0MPa(22-145psi)(1.5-10.0bar) | |||||||||

| Single acting | 0.2-1.0MPa(28-145psi)(2.0-10.0bar) | ||||||||||

| Proof pressure | 1.5MPa(215psil)(15bar) | ||||||||||

| Temperature℃ | 0-70℃ | ||||||||||

| Speed range mm/s | Double acting: 30~500 Single acting: 50~500 | ||||||||||

| Stroke tolerance | Stroke≤100⁺₀¹·⁰ Stroke>100⁺₀¹·⁵ | ||||||||||

| Cushion type | Bumper | ||||||||||

| Port size | M5*0,8 | 1/8″ | 1/4″ | 3/8″ | |||||||

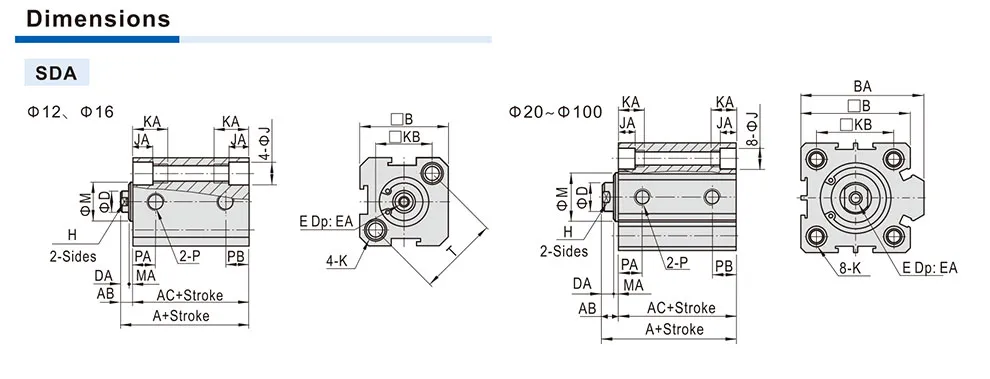

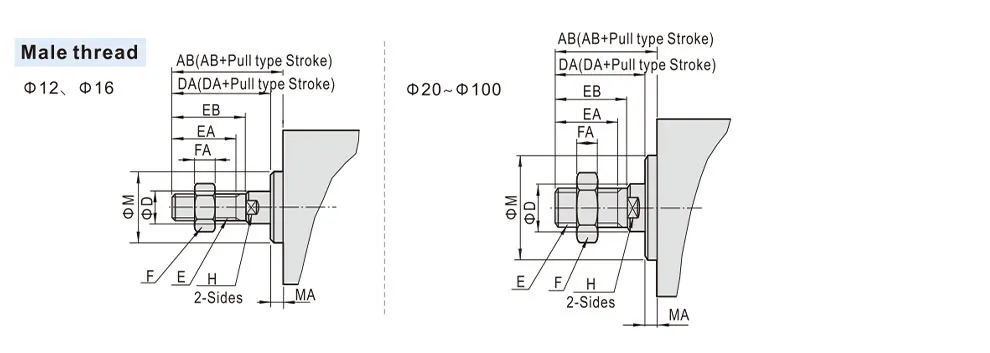

| Item Bore size | A | AC | A | AC | AB | B | BA | D | DA | E | EA | H | J | JA | K | KA | KB | M | MA | P | PA | PB | T | ||

| Without magnet | With magnet | St=5 | St>5 | St=5 | St>5 | ||||||||||||||||||||

| 12 | 22 | 17 | 32 | 27 | 5 | 25 | – | 6 | 4 | M3*0.5 | 6 | 5 | 6.5 | 4.5 | M5*0.8Thru.hole:4.2 | 12 | 16.3 | 10.2 | 1 | M5*0.8 | 7.5 | 7.5 | 5 | 5 | 23 |

| 16 | 24 | 18.5 | 34 | 28.5 | 5.5 | 29 | – | 6 | 4 | M3*0.5 | 6 | 5 | 6.5 | 4.5 | M5*0.8Thru.hole:4.2 | 12 | 19.8 | 11 | 1.5 | M5*0.8 | 8 | 8 | 5 | 5.5 | 28 |

| 20 | 25 | 19.5 | 35 | 29.5 | 5.5 | 34 | 36 | 8 | 4 | M4*0.7 | 8 | 6 | 6.5 | 4.5 | M5*0.8Thru.hole:4.2 | 14 | 24 | 13 | 1.5 | M5*0.8 | 8 | 9 | 5 | 5.5 | – |

| 25 | 27 | 21 | 37 | 31 | 6 | 40 | 42 | 10 | 4 | M5*0.8 | 10 | 8 | 8.2 | 5.5 | M6*1.0Thru.hole:5.2 | 15 | 28 | 17 | 2 | M5*0.8 | 9 | 9 | 5.5 | 5.5 | – |

| 32 | 31.5 | 24.5 | 41.5 | 34.5 | 7 | 44 | 50 | 12 | 4.5 | M6*1.0 | 12 | 10 | 8.2 | 5.5 | M6*1.0Thru.hole:5.2 | 16 | 34 | 22 | 2.5 | 1/8″ | 9 | 9 | 6.5 | 9 | – |

| 40 | 33 | 26 | 43 | 36 | 7 | 52 | 58.8 | 16 | 4 | M8*1.25 | 12 | 14 | 10.5 | 6.5 | M8*1.25Thru.hole:6.7 | 20 | 40 | 28 | 3 | 1/8″ | 9.5 | 9.5 | 7.5 | 7.5 | – |

| 50 | 37 | 28 | 47 | 38 | 9 | 62 | 71.5 | 20 | 5 | M10*1.5 | 15 | 17 | 10.5 | 6.5 | M8*1.25Thru.hole:6.7 | 25 | 48 | 38 | 4 | 1/4″ | 8 | 10.5 | 8 | 10.5 | – |

| 63 | 41 | 32 | 51 | 42 | 9 | 75 | 84.5 | 20 | 5 | M10*1.5 | 15 | 17 | 10.5 | 6.5 | M8*1.25Thru.hole:6.7 | 25 | 60 | 40 | 4 | 1/4″ | 9.5 | 12 | 9.5 | 11 | – |

| 80 | 52 | 41 | 62 | 51 | 11 | 94 | 104 | 25 | 6 | M14*1.5 | 20 | 22 | 17 | 11 | M12*1.75Thru.hole:10.4 | 25 | 74 | 45 | 5 | 3/8″ | 11.5 | 14.5 | 11.5 | 14.5 | – |

| 100 | 63 | 51 | 73 | 61 | 12 | 114 | 124 | 32 | 7 | M18*1.5 | 20 | 27 | 19 | 13 | M14*2.0Thru.hole:12.4 | 30 | 90 | 55 | 5 | 3/8″ | 16 | 20.5 | 16 | 20.5 | – |

Detailed Applications

Automated Production Lines: Precise actuation for assembly, packaging, and handling systems where space is limited.

Robotic Equipment: Lightweight and compact cylinders ideal for robotic arms and compact automation.

Electronic Manufacturing: Small footprint pneumatic cylinders for delicate component placement.

Food Processing Machinery: Suitable for clean environments due to corrosion-resistant materials.

Material Handling: Reliable stroke control and positioning for conveyors and pick-and-place machines.

General Industrial Automation: Versatile pneumatic actuators for a wide range of compact machinery.

How to Select the Right SDA Series Pneumatic Actuator

Choose Bore Size and Stroke: Based on required force output and travel distance.

Determine Acting Type: Select single acting for spring return or double acting for push-pull motions.

Sensor Requirements: Opt for models with magnetic sensor slots for position detection needs.

Mounting Style Compatibility: Consider your machinery’s design for bracket choice.

Operating Conditions: Factor in pressure, temperature, and environment for material suitability.

Installation Space: Ensure selected cylinder fits within spatial constraints of the machine.

Request a Quote Now

Our team will get back to you within 24 hours.