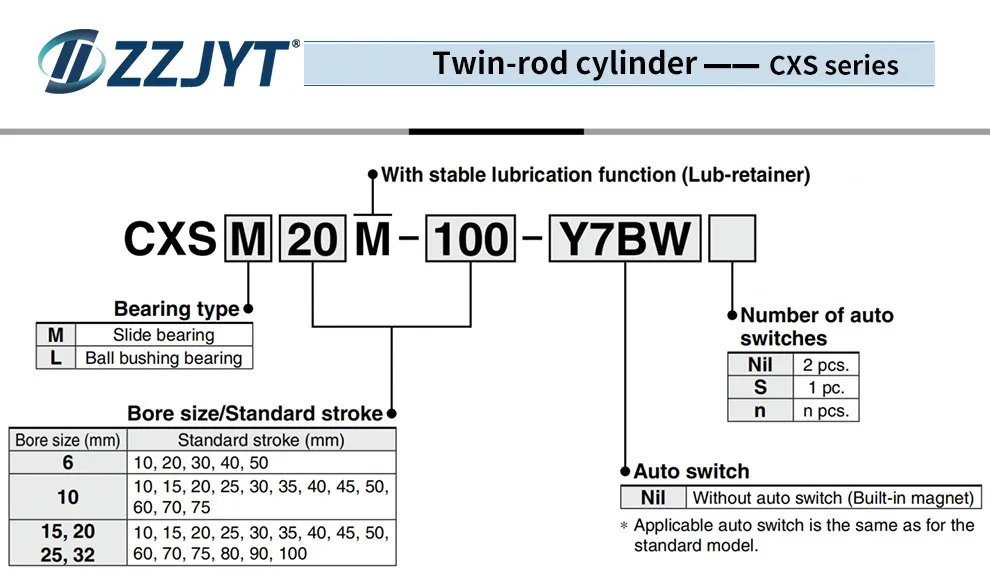

The CXSM Series mini cylinder air actuator offers dual rod design for more stable, non-rotating operation, ensuring accurate and consistent movement crucial in high-precision assembly and manufacturing processes. Built with high-quality materials and slide bearing guides, the CXSM provides excellent durability, protection from side load impacts, and extended service life. Bore sizes typically range from 6mm to 32mm, with stroke lengths customizable up to 100mm or more depending on application needs. The series complies with ISO standards, facilitating easy integration and interchangeability with other ISO-compliant pneumatic components. This ensures seamless installation and maintains compatibility across global industrial platforms.

Key Features and Advantages

Dual Rod Guided Design: Prevents rotation, increasing stability and precision in linear motion.

ISO Compatible: Designed in line with ISO standards for easy replacement and integration.

Durable Slide Bearing Construction: Provides resistance to side loads, reducing wear and improving operational lifespan.

Wide Bore and Stroke Range: Bore sizes from 6mm to 32mm with strokes up to 100mm or tailored to specific needs.

High Precision Motion: Achieves non-rotating accuracy within ±0.1° to ±0.2°, suitable for sensitive applications.

Built-in Magnetic Sensor Mounting: Supports effortless sensor installation for position detection.

Operating Pressure Range: Typically from 0.1 to 1.0 MPa for effective force delivery.

Versatile Mounting Options: Can be mounted from multiple sides, enhancing installation flexibility.

Robust Build for Harsh Environments: Use of high-grade materials and seals ensures reliable function in industrial conditions.

Installation and Maintenance

Installation

Mount the cylinder on a flat surface with recommended mounting accessories (foot, flange, clevis).

Ensure the piston rod is fully retracted during mounting to avoid damage.

Connect pneumatic air supply lines with clean and dry air to prolong the lifespan of seals and reduce leakage.

Install magnetic sensors in the built-in grooves if position feedback is required.

Test cylinder operation and check for air leaks before full system integration.

Maintenance

Regularly inspect piston rods and seals for wear or damage.

Maintain cleanliness of the cylinder exterior and piston rod to prevent contamination.

Replace seals at signs of leakage or decreased performance.

Lubricate seals and moving parts only if specified by the manufacturer.

Avoid operations exceeding temperature and pressure limits to prevent damage.

| Bore size (mm) | 6 | 10 | 15 | 20 | 25 | 32 |

| Bearing type | Slide bearing | |||||

| Minimum operating pressure | 0.2MPa | 0.15MPa | 0.1MPa | |||

| Piston speed | 50 to 800 mm/s | 50 to 700 mm/s | 50 to 600 mm/s | |||

| Other specifications | Same as the standard model | |||||

| Dimensions | See below | |||||

| Model | K | L | R |

| CXS_ 10 | 4 | 25 | 35 |

| CXS_ 15 | 3 | 36 | 44.5 |

| CXS_ 20 | 6 | 36 | 50.5 |

| CXS_ 25 | 6 | 36 | 52 |

| CXS_ 32 | 4 | 40 | 66 |

| Stroke Model | SS | ||||||||||||||

| 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 75 | 80 | 90 | 100 | |

| CXS_ 10 | 70 | 78 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 120 | 130 | 135 | / | / | / |

| CXS_ 15 | 76 | 84 | 86 | 91 | 96 | 101 | 106 | 111 | 116 | 126 | 136 | 141 | 146 | 156 | 166 |

| CXS_ 20 | 86 | 91 | 96 | 101 | 106 | 111 | 116 | 121 | 126 | 136 | 146 | 151 | 156 | 166 | 176 |

| CXS_ 25 | 88 | 93 | 98 | 103 | 108 | 113 | 118 | 123 | 128 | 138 | 148 | 153 | 158 | 168 | 178 |

| CXS_ 32 | 102 | 107 | 112 | 117 | 122 | 127 | 132 | 137 | 142 | 152 | 162 | 167 | 172 | 182 | 192 |

Detailed Applications

Automation and Assembly Lines: Precise, stable actuation critical in manufacturing and packaging processes.

Material Handling Systems: Excellent linear guidance for reliable pick-and-place and transfer tasks.

Electronics Manufacturing: Non-rotating cylinders suitable for intricate component positioning.

Automotive Production: Robust cylinders capable of withstanding industrial loads and repetitive movements.

Food Industry Processing: Corrosion-resistant variants available for hygienic and demanding environments.

Medical Equipment Automation: Reliable, guided motion for precision assembly and handling.

How to Select the Right CXSM Mini Cylinder

Bore Size and Stroke: Choose based on required force and travel distance.

Mounting Requirements: Compatible with multiple mounting configurations; select based on machine design.

Operating Pressure Range: Ensure pneumatic supply matches cylinder specifications.

Sensor Compatibility: Opt for magnetic sensor-ready models if position detection is necessary.

Environmental Considerations: Assess material and sealing for resistance to specific conditions.

Precision Requirements: Select for non-rotating accuracy and guided motion suited for sensitive operations.

Request a Quote Now

Our team will get back to you within 24 hours.