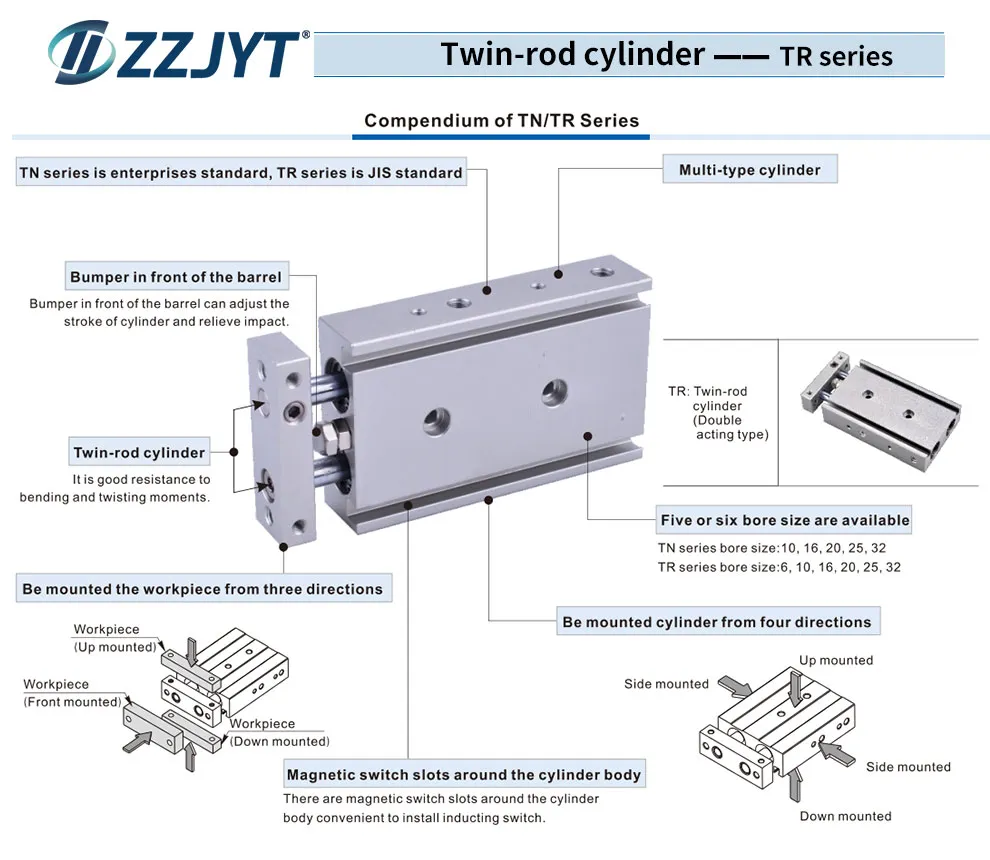

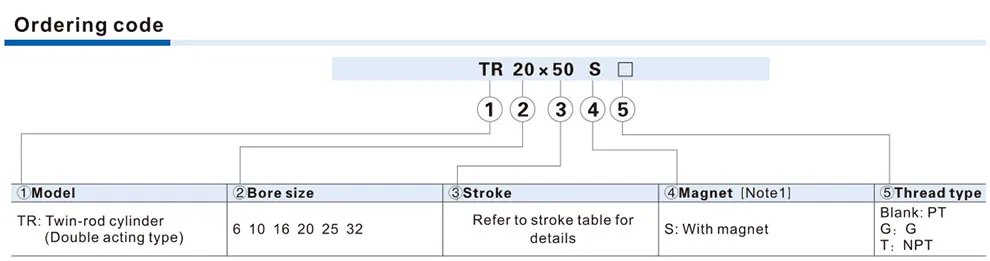

The TR Series dual-rod mini pneumatic cylinder meets JIS standards and is engineered for high precision and durability. The series utilizes advanced seal materials such as urethane and fluoroelastomer (FKM), which provide excellent resistance to wear, chemicals, and high temperatures. The hard chrome-plated piston rods paired with a hard-coated cylinder bore reduce friction and abrasion, extending the service life of the cylinder. This series is designed with non-lubricated sliding guides for smooth, consistent motion without additional maintenance. With bore sizes ranging typically from 6mm to 32mm and stroke lengths up to 200mm, the TR Series is suitable for industrial automation, manufacturing, and robotic applications requiring high reliability and precision.

Key Features and Advantages

High Durability Seal Materials: Urethane rod seals and FKM seals for high temperature and chemical resistance.

Dual Rod Non-Rotating Design: Provides stability, preventing piston rotation and resisting side loads.

Hard Chrome Plated Piston Rods and Hard-Coated Cylinder Barrel: Minimize wear and enhance longevity.

JIS Standard Compliant: Ensures easy integration with other ISO/JIS standard pneumatic components.

Lubrication-Free Sliding Guide Bearings: Allow maintenance-free operation with smooth piston travel.

Integrated Magnetic Sensors (Optional): Available slots for magnetic sensor installation enhance automation control.

Multiple Mounting Options: Includes foot, flange, clevis, and pivot mounts to suit various installation requirements.

Adjustable Stroke and Cushioning: Stroke adjustment and crash pads protect the cylinder during operation.

Wide Operating Pressure and Temperature: Operates reliably within 0.1 to 1.0 MPa and temperatures from -20°C to 70°C.

Detailed Applications

Automated Assembly Lines: High precision actuation avoids rotation for exact positioning.

Robotics: Stable, durable cylinders for controlled movements.

Packaging and Material Handling: Reliable cylinders with cushioning to reduce impact damage.

Electronics Manufacturing: Compact size and precise motion control for sensitive components.

Food and Beverage Industry: High corrosion resistance suitable for hygienic environments.

General Industrial Automation: Versatile, high-durability cylinders for various machine types.

| Bore size(mm) | 6 | 10 | 16 | 20 | 25 | 32 |

| Acting type | Double acting | |||||

| Fluid | Air(to be filtered by 40 μ m fiter element) | |||||

| Operating pressure | 0.15~1.0MPa(22~145psi) | |||||

| Proof pressure | 1.5MPa(215psi) | |||||

| Temperature℃ | -20~70 | |||||

| Speed range mm/s | 30~500 | |||||

| Adjustable stroke mm | -5~0 | |||||

| Stroke tolerance | ≤100⁺ₒ¹·⁰ >100⁺₀¹·⁵ | |||||

| Cushion type | Bumper | |||||

| Non-rotating tolerance | ±0.2° | ±0.15° | ±0.1° | |||

| Port size | M5*0.8 | 1/8″ | ||||

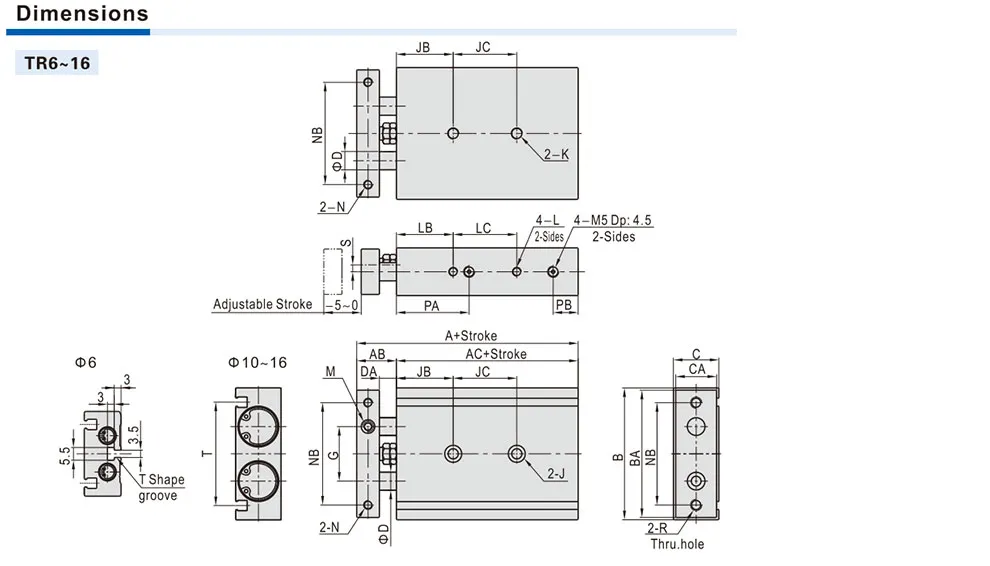

| Bore sizeItem(TR6~16) Stroke | A | AB | AC | B | BA | C | CA | D | DA | G | T |

| 6 | 58.5 | 13.5 | 45 | 37 | 35 | 16 | 14 | 4 | 8 | 16 | 23 |

| 10 | 72 | 17 | 55 | 46 | 44 | 17 | 15 | 6 | 9 | 20 | 36.5 |

| 16 | 79 | 19 | 60 | 58 | 56 | 20 | 18 | 8 | 9 | 25 | 46.5 |

| Bore sizeItem(TR6~16) | JB | K | L | LB | M | N | NB | PA | PB | R | S |

| 6 | 13 | – | M3*0.5Dp:4.5 | 10 | M3*0.5 | M3*0.5Thru.hole | 28 | 24.5 | 6.5 | M5*0.5 | 4.5 |

| 10 | 20 | M4*0.7Thru.thread | M3*0.5Dp:5 | 20 | M5*0.8 | M3*0.5Dp:7.5 | 35 | 30 | 8 | M4*0.7 | 3.5 |

| 16 | 30 | M5*0.8Thru.thread | M5*0.7Dp:5 | 30 | M6*1.0 | M4*0.7Thru.hole | 45 | 38 | 8 | M5*0.8 | 5 |

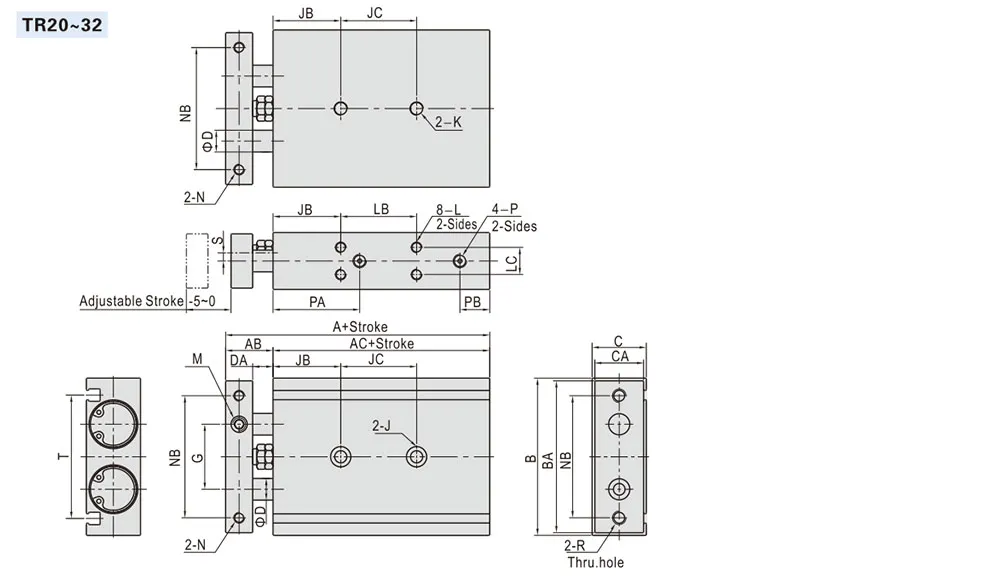

| Bore sizeItem(TR20~32) Stroke | A | AB | AC | B | BA | C | CA | D | DA | G | JB | P | PA | PB |

| 20 | 94 | 24 | 70 | 64 | 62 | 25 | 23 | 10 | 12 | 28 | 30 | M5*0.8 | 46 | 9 |

| 25 | 96 | 24 | 72 | 80 | 78 | 30 | 28 | 12 | 12 | 35 | 30 | 1/8″ | 43 | 9 |

| 32 | 112 | 30 | 82 | 98 | 96 | 38 | 36 | 16 | 14 | 44 | 30 | 1/8″ | 53 | 10 |

| Bore sizeItem(TR20~32) | K | L | LC | M | N | NB | R | S | T | |||||

| 20 | M6*1.0 | M4*0.7Dp:5.5 | 9.5 | M8*1.25 | M4*0.7Dp:6 | 50 | M5*0.8 | 6.5 | 52 | |||||

| 25 | M8*1.25 | M5*0.8Dp:7.5 | 13 | M8*1.25 | M5*0.8Dp:7.5 | 60 | M6*1.0 | 9 | 61 | |||||

| 32 | M8*1.25 | M5*0.8Dp:8 | 20 | M10*1.5 | M5*0.8Dp:8 | 75 | M6*1.0 | 11.5 | 73 |

Installation and Maintenance

Installation

Select mounting style as per application demands and securely fasten the cylinder.

Connect clean, filtered air supply lines; ensure no dust or oil contamination.

Install magnetic sensors into the designated grooves if monitoring of piston position is needed.

Adjust stroke length and cushioning pads for optimal impact absorption.

Check all fittings for air tightness before commencing full operation.

Maintenance

Periodically inspect seals, piston rods, and bearings for wear or damage.

Replace seals promptly on signs of leakage to maintain system pressure.

Clean piston rod and cylinder body surfaces regularly to prevent contamination.

Lubrication is not typically necessary due to self-lubricating materials but follow manufacturer instructions.

Avoid exposing the cylinder to excessive moisture, chemicals, or extreme temperatures.

How to Select the Right TR Series Miniature Cylinder

Bore Size and Stroke Length: Choose based on force requirements and needed travel distance.

Seal Material: Opt for FKM seals for high temperature or chemical exposures; urethane seals for general use.

Mounting Options: Foot, flange, or clevis mounting depending on machine design.

Magnetic Sensor Integration: Select cylinders with sensor grooves if feedback control is necessary.

Operating Environment: Consider temperature, pressure, and chemical exposure when selecting materials.

Precision and Strength Needs: Dual rod design ensures high precision and side load resistance.

Request a Quote Now

Our team will get back to you within 24 hours.