The CDJ2B series miniature pneumatic cylinder offers a robust double-acting mechanism with stainless steel construction, making it corrosion-resistant and suitable for demanding industrial applications. With bore sizes ranging from 6mm to 16mm and operational pressure up to 1.0 MPa, this cylinder accommodates a variety of compact automation tasks. It provides smooth linear motion, high precision, and effortless operation in manufacturing, packaging, robotics, and medical device automation. Non-lubricated and low maintenance, the CDJ2B cylinder is designed to optimize productivity while minimizing downtime.

Key Features and Advantages

Compact and Lightweight Design: Saves valuable space in tight automation setups without compromising performance.

Durable Stainless Steel Body: Ensures excellent resistance to corrosion and wear for extended service life.

Double Acting Pneumatic Cylinder: Provides reliable push and pull forces with high precision.

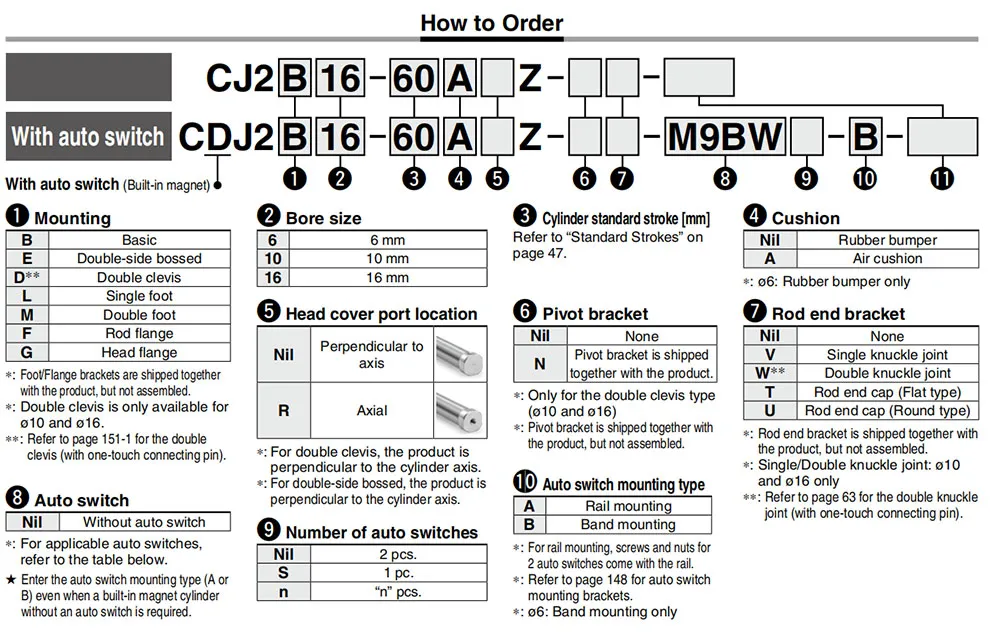

Wide Bore Size Range: Available in 6mm, 10mm, and 16mm to fit varied automation needs.

High Operating Pressure: Supports pressures up to 1.0 MPa for versatile industrial applications.

Temperature Range: Operates reliably between -10°C and 60°C for use in diverse environments.

Magnetic Sensor Compatibility: Supports integration with magnetic sensors for position feedback and smart automation.

Non-Lubricated Operation: Reduces maintenance requirements and improves operational efficiency.

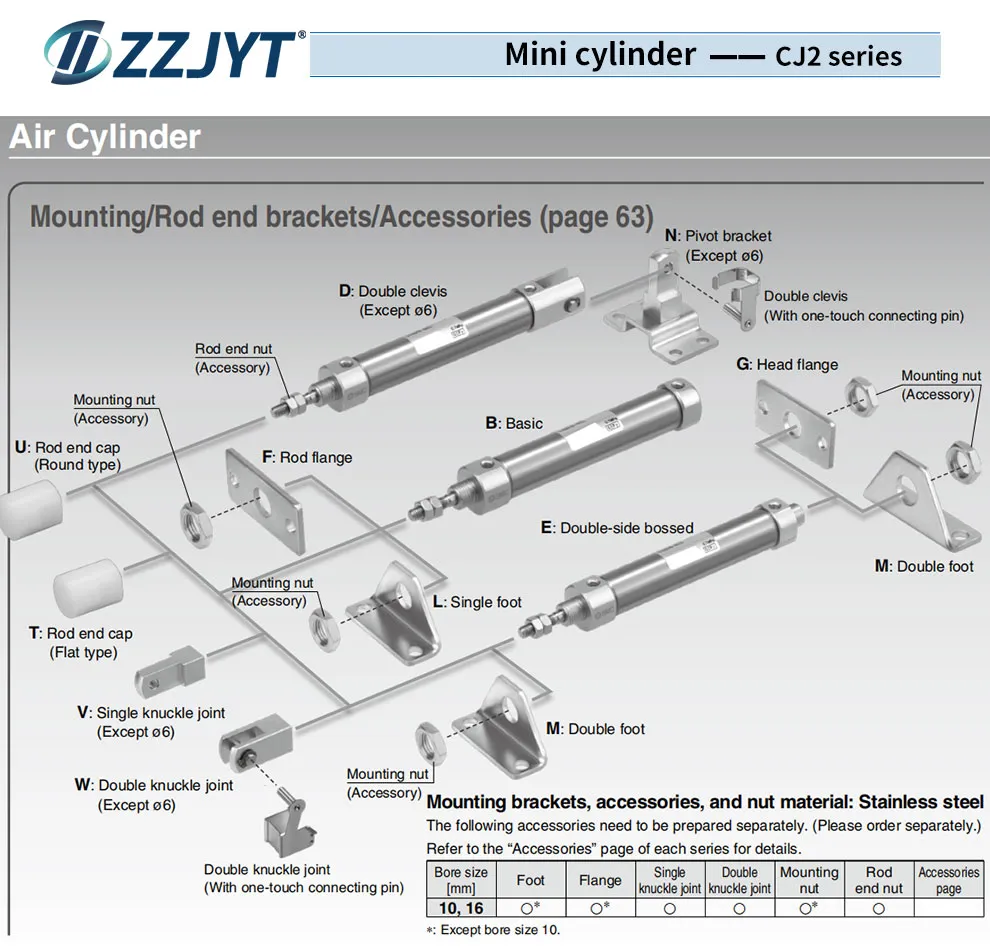

Multiple Mounting Options: Includes double clevis, foot, flange, and rod end brackets for flexible installation.

| Bore size(mm) | 6 | 10 | 16 |

| Fluid | Air (to be filtered by 40 u m filter element) | ||

| Acting type | Double acting | ||

| Maximum operating pressure Mpa | 0.7 | ||

| Minimum operating pressure Mpa | 0.12 | 0.06 | |

| Ambient and fluid temperatures | With magnetic switch:-10℃~70℃ Without magnetic switch:-10℃~60℃ | ||

| Piston speed | 50~750mm/s | ||

| Buffer | Rubber buffer/air buffer | ||

| Stroke tolerance (mm) | ₊₀º·¹ | ||

| Give oil | NO | ||

| Port size | M5*0.8 | ||

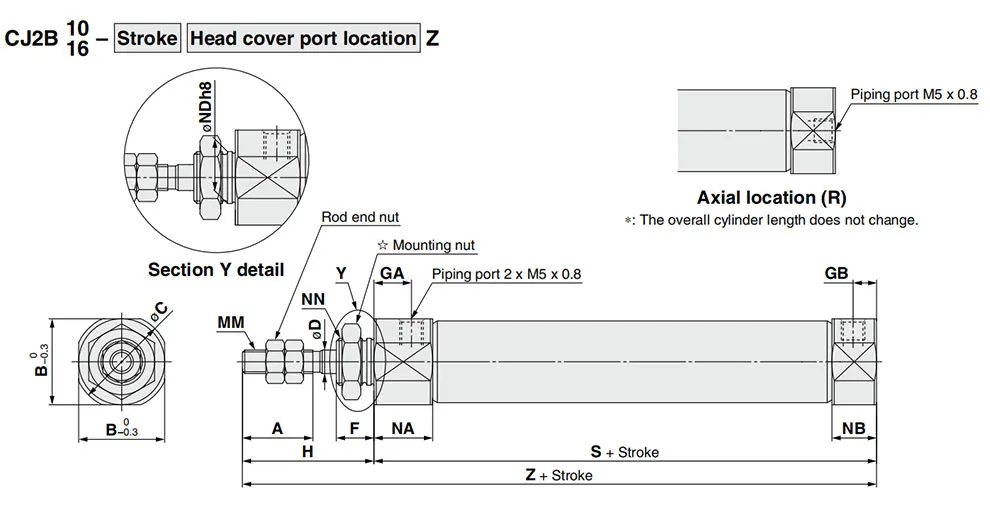

| Bore size/Item | A | B | C | D | F | GA | GB | H | MM | NA | NB | Hdh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3*0.5 | 16 | 7 | 6 | M6*1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4*0.7 | 12.5 | 9.5 | 8 | M8*1.0 | 46 | – | 74 |

| 16 | 15 | 18.3 | 20 | 5 | 8 | 8 | 5 | 28 | M5*0.8 | 12.5 | 9.5 | 10 | M10*1.0 | 47 | – | 75 |

Installation and Maintenance Steps

Installation

Mount the cylinder securely using the recommended bracket type suitable for your application (e.g., double clevis or foot mount).

Connect pneumatic lines ensuring clean, dry compressed air to prevent contamination.

For cylinders equipped with magnetic sensors, carefully install the sensor on the cylinder body with easy fine adjustment.

Follow pressure guidelines to avoid over-pressurization and ensure safety.

Maintenance

Regularly check air supply filters and dryers to maintain clean air flow and extend seal life.

Inspect cylinder seals for wear and replace if air leakage or friction issues arise.

Apply recommended grease only during seal replacement or extensive maintenance to prolong cylinder lifespan.

Avoid operating in corrosive environments without proper protective covers.

Keep pneumatic tubing as short as possible to avoid pressure drops and moisture buildup.

Detailed Applications

The CDJ2B miniature cylinder is ideal for:

Robotics: Compact actuators for robotic arms and precision movement.

Packaging Systems: Automated packing, sorting, and assembly lines needing precise linear actuation.

Medical Equipment: Lightweight and corrosion-resistant cylinders for medical device automation.

Food and Beverage Production: Stainless steel design suitable for hygienic environments.

Electronics Manufacturing: Precise component placement and lightweight automation.

Automotive Assembly: Space-saving pneumatic solutions for assembly line automation.

How to Select the Right CDJ2B Miniature Cylinder

When choosing a CDJ2B pneumatic cylinder for your application, consider:

Bore Size: Select based on force requirements; larger bore for higher force.

Stroke Length: Determine required linear movement to specify stroke within 10-150mm available range.

Operating Environment: Evaluate temperature and corrosion exposure; stainless steel is preferred for harsh conditions.

Mounting Style: Match mounting options to machine design for secure, easy installation.

Sensor Needs: Choose models with magnetic sensors for automation requiring position feedback.

Pressure Requirements: Ensure maximum operating pressure does not exceed 1.0 MPa.

Request a Quote Now

Our team will get back to you within 24 hours.