The CM2 Small Pneumatic Actuator mini cylinder offers robust double-acting performance in a compact form factor, ideal for various industrial automation needs. Manufactured with corrosion-resistant materials like stainless steel or anodized aluminum, this series delivers excellent durability and long service life. Its design supports a wide range of bore sizes and strokes, making it flexible for precision positioning in assembly lines, packaging machinery, and other industrial equipment. The CM2 series also includes standard and optional features like built-in cushions, various mounting brackets, and auto switches for seamless integration and control.

Key Features and Advantages

Compact and Lightweight Design: Saves space and fits seamlessly into tight machine layouts.

Durable Construction: Stainless steel and aluminum bodies ensure corrosion resistance and longevity.

Double Acting with Single Rod: Provides reliable push and pull linear motion.

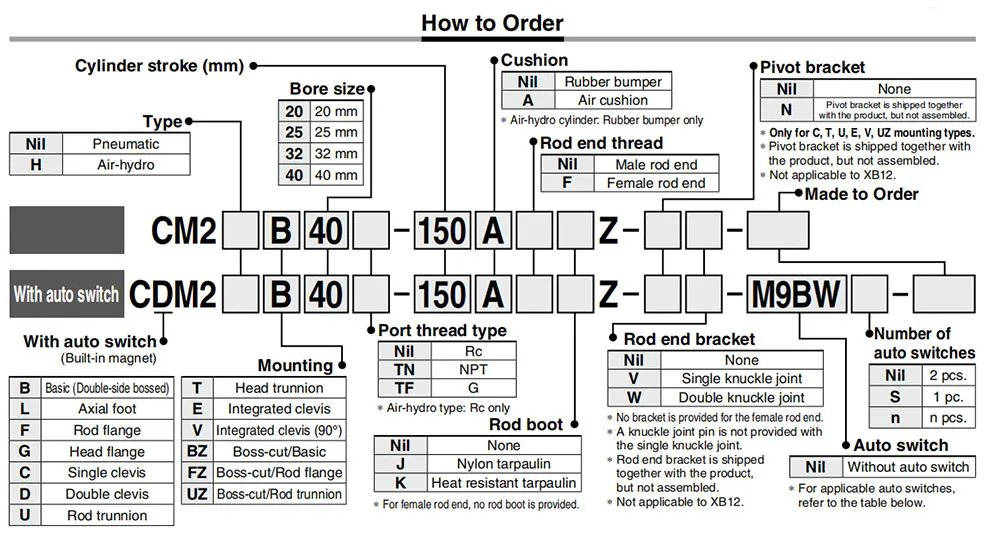

Wide Range of Bore Sizes and Strokes: Flexible selection from 20mm to 40mm bore sizes and strokes up to 500mm.

Built-in Rubber Cushions: Standard cushioning for smooth operation and shock absorption.

Optional Auto Switch Mounts: For position sensing and automation feedback.

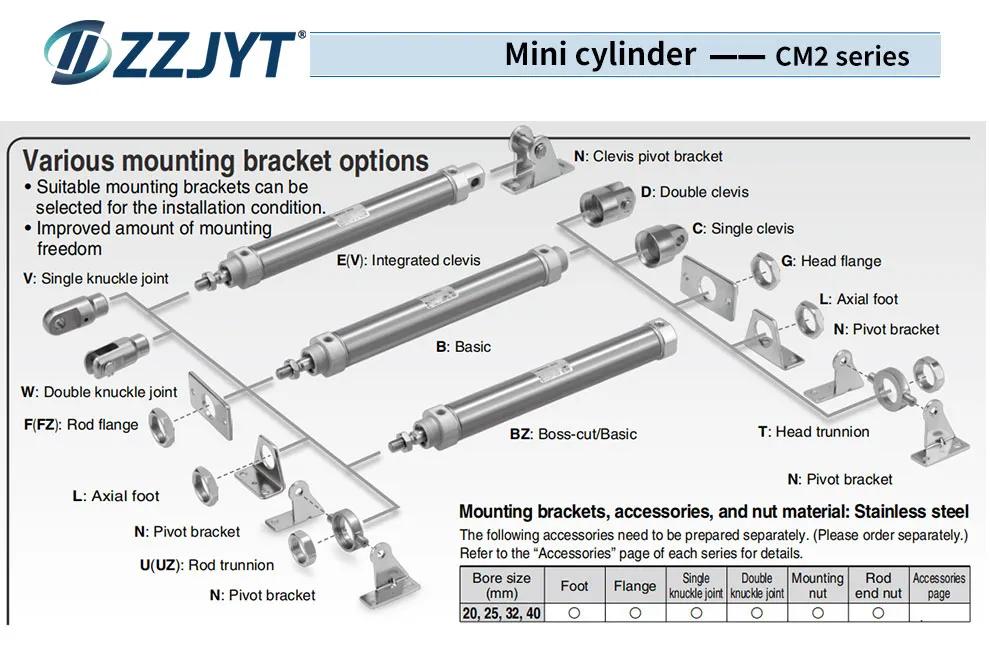

Multiple Mounting Options: Foot, flange, clevis, and trunnion mounts available to suit installation needs.

Excellent Dust-proof Performance: Special sealing design adapts to harsh industrial environments.

High Operating Pressure: Up to 1.0 MPa for strong force output.

Wide Operating Temperature Range: From -10°C to +70°C, adaptable to various industrial conditions.

| Bore size(mm) | 20 | 25 | 32 | 40 | ||

| Type | Pneumatic | |||||

| Action | Double acting,Single rod | |||||

| Fluld | Air | |||||

| Proof pressure | 1.5MPa | |||||

| Maximum operating pressure | 1.0MPa | |||||

| Minimum operating pressure | 0.05MPa | |||||

| Ambient and fluid temperature | Without auto switch:-10℃~70℃((No freezing) With auto switch:-10℃~60℃((No freezing) | |||||

| Lubrication | Not required (Non-lube) | |||||

| Piston speed | Rubber bumper:50~750mm/s | |||||

| Cushion | Rubber bumper, Air cushion | |||||

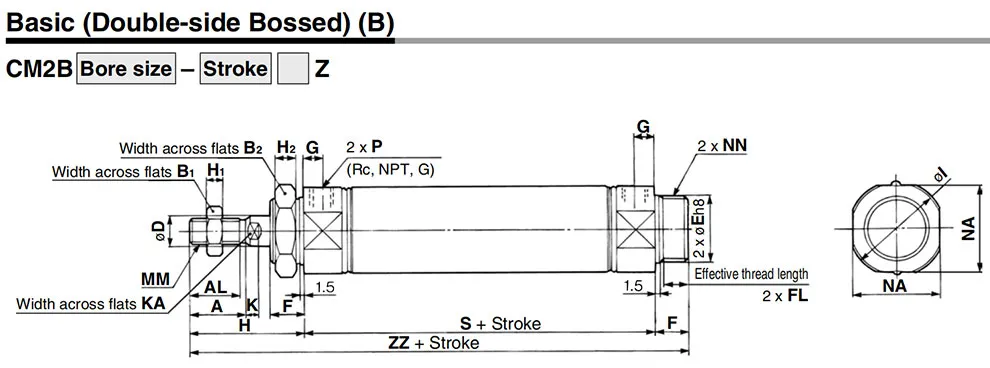

| Bore size(mm) | A | AL | B1 | B2 | D | E | F | FL | G | H | H1 | H2 | I | K | KA | MM | NA | NN | P | S | ZZ |

| 20 | 18 | 15.5 | 13 | 26 | 8 | 20_⁰₀․₀₃₃ | 13 | 10.5 | 8 | 41 | 5 | 8 | 28 | 5 | 6 | M8*1.25 | 24 | M20×1.5 | 1/8 | 62 | 116 |

| 25 | 22 | 19.5 | 17 | 32 | 10 | 26_⁰₀․₀₃₃ | 13 | 10.5 | 8 | 45 | 6 | 8 | 33.5 | 5.5 | 8 | M10*1.25 | 30 | M26×1.5 | 1/8 | 62 | 120 |

| 32 | 22 | 19.5 | 17 | 32 | 12 | 26_⁰₀․₀₃₃ | 13 | 10.5 | 8 | 45 | 6 | 8 | 37.5 | 5.5 | 10 | M10*1.25 | 34.5 | M26×1.5 | 1/8 | 64 | 122 |

| 24 | 24 | 21 | 22 | 41 | 14 | 32_⁰₀․₀₃₉ | 16 | 13.5 | 11 | 50 | 8 | 10 | 46.5 | 7 | 12 | M14*1.5 | 42.5 | M32×2 | 1/4 | 88 | 154 |

Installation and Maintenance

Installation

Choose appropriate mounting brackets based on machine design.

Securely mount the cylinder using recommended hardware to prevent misalignment.

Connect pneumatic tubing with standard one-touch fittings for leak-free operation.

Install auto switches if positional feedback is required; adjust the switch position for accuracy.

Ensure the air supply pressure matches the cylinder specifications to avoid damage.

Maintenance

Regularly inspect seals and pneumatic connections for leaks or wear.

Periodically clean the piston rod and cylinder body to prevent contamination.

Lubricate moving parts only if specified by manufacturer guidelines.

Replace worn seals immediately to maintain performance.

Avoid exposure to corrosive chemicals or extreme temperatures without protective measures.

Detailed Applications

The CM2 mini cylinder is widely applied in:

Assembly Line Automation: Precise linear actuation for component handling.

Packaging Machinery: Consistent performance in packing and sorting operations.

Food and Beverage Industry: Suitable for hygienic environments with corrosion-resistant builds.

Robotics: Small footprint actuators for compact robotic arms.

Electronics Manufacturing: Accurate positioning in sensitive electronic assembly.

Automotive Industry: Durable cylinders for repetitive tasks on production lines.

General Industrial Automation: Versatile for various light-to-medium duty applications.

How to Select the Right CM2 Mini Cylinder

Determine Bore Size: Based on required force output; larger bore yields higher force.

Select Stroke Length: Choose according to the required linear travel distance.

Material Selection: Stainless steel for corrosive or clean environments; aluminum for standard use.

Mounting Style: Match mounting options (foot, flange, clevis) to machine setup.

Cushioning Needs: Decide on built-in rubber cushions or air cushions for impact damping.

Auto Switch Requirements: Choose cylinder models with mounting provisions for switches if automation feedback is needed.

Operating Conditions: Confirm temperature range and pressure compatibility with application demands.

Request a Quote Now

Our team will get back to you within 24 hours.