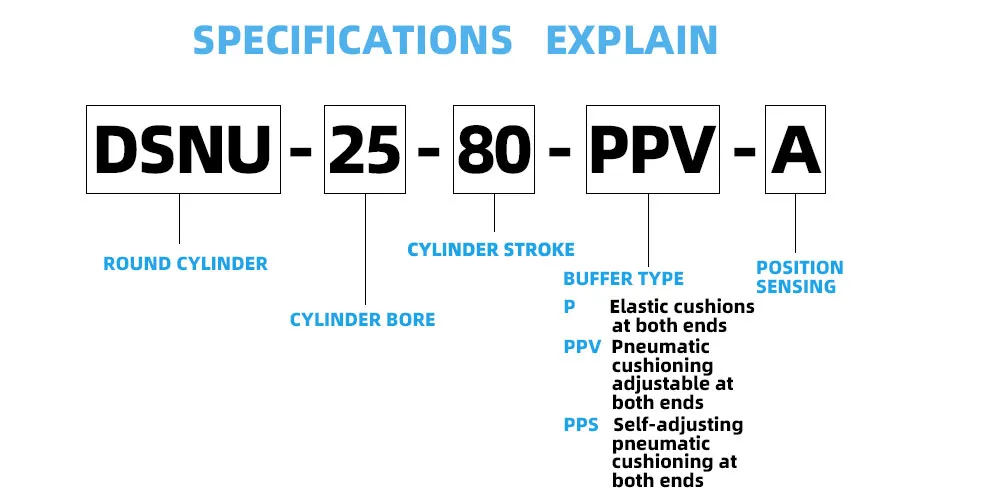

The DSNU miniature pneumatic cylinder adheres to the ISO 6432 standard and is widely acclaimed for its compact dimensions combined with exceptional precision and durability. It features a robust stainless steel cylinder barrel and piston rod, making it highly resistant to corrosion and wear in industrial settings. Available in bore sizes ranging from 8mm to 63mm with strokes from 1mm up to 500mm, the DSNU series supports diverse assembly line automation tasks. One of its standout features is the adjustable pneumatic cushioning at both ends, which minimizes impact forces and noise while improving cycle reliability and lifespan. The series also offers variants with self-adjusting cushioning that automatically adapts to changes in load and speed, making it ideal for fast, repetitive operations.

Key Features and Advantages

High Precision and Smooth Operation: Low friction seals and stainless steel components ensure accurate, stick-slip-free movement.

Adjustable Pneumatic Cushioning: Cushions on both ends can be adjusted or self-adjusted, reducing impact and enhancing operational safety.

Wide Bore Size and Stroke Range: Bore sizes from 8mm to 63mm and strokes up to 500mm fit various automation requirements.

Robust Stainless Steel Cylinder Barrel and Piston Rod: Delivers outstanding corrosion resistance and durability in harsh environments.

ISO 6432 Standard Compliance: Guarantees compatibility with many automation components and accessories.

Magnetic Piston for Position Sensing: Enables easy integration of proximity sensors for precise position feedback.

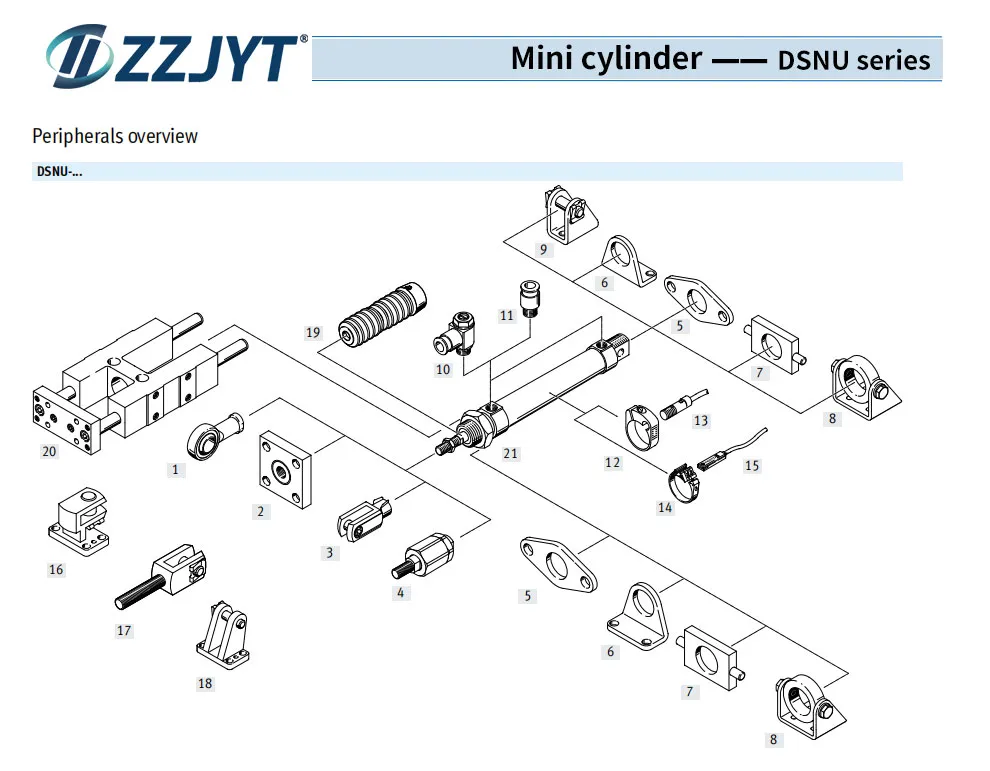

Multiple Mounting Options: Includes direct mounting, threaded flange, and mounting accessories for versatile installation.

Broad Operating Temperature Range: Functions reliably between -20°C and 80°C.

No Lubrication Required: Designed for maintenance ease and long service intervals.

| General technical data Piston | 8 | 10 | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 |

| Conforms to standard | ISO 6432 | – | ||||||||

| Pneumatic connection | M5 | M5 | M5 | M5 | G1/8 | G1/8 | G1/8 | G1/4 | G1/4 | G3/8 |

| Piston rod thread | M4 | M4 | M6 | M6 | M10*1.25 | M10*1.25 | M12*1.25 | M12*1.25 | M16*1.5 | M16*1.5 |

| Stroke1) | 1 … 100 | 1 … 200 | 1 … 320 | 1 … 500 | ||||||

| Design | Piston/piston rod/cylinder barrel | |||||||||

| Cushioning | ||||||||||

| DSNU-…-P | Elastic cushioning rings/plates at both ends | |||||||||

| DSNU-…-PPV | – | Cushioning, adjustable at both ends | ||||||||

| Cushioning length | ||||||||||

| DSNU-…-PPV | – | 9 | 12 | 15 | 17 | 14 | 18 | 20 | 21 | |

| Position sensing | Via proximity switch | |||||||||

| Type of mounting | Direct mounting (variant MH only | |||||||||

| With accessories | ||||||||||

| Mounting position | Any | |||||||||

| Weight [g] | ||||||||||

| Product weight with 0 mm stroke | 34.6 | 37.3 | 75 | 89.9 | 186.8 | 238 | 370.5 | 661 | 1087 | 1445 |

| Additional weight per 10 mm stroke | 2.4 | 2.7 | 4 | 4.6 | 7.2 | 11 | 15.5 | 24 | 40 | 44 |

| Moving mass with 0 mm stroke | 7.5 | 8.5 | 18.5 | 23 | 44 | 71 | 121 | 230 | 413 | 459 |

| Moving mass per 10 mm stroke | 1 | 1 | 2 | 2 | 4 | 6 | 9 | 16 | 25 | 25 |

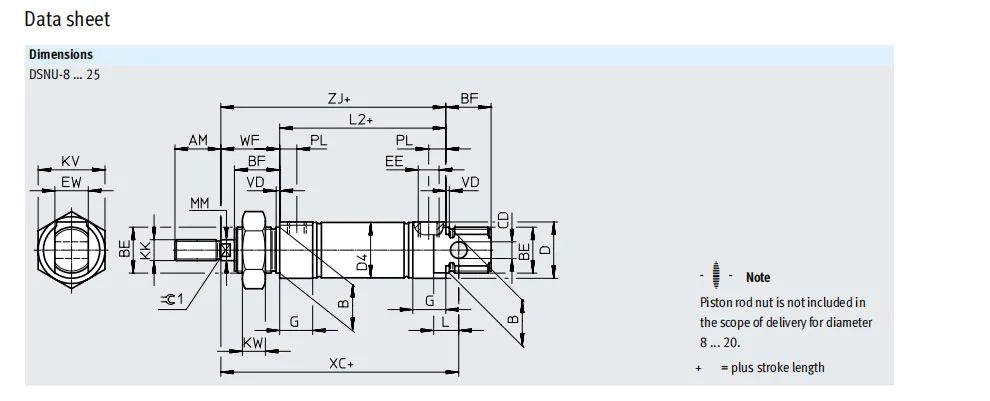

| Ø【mm】 | AM | B | BE | BF | CD | D | D4 | EE | EW | G | KK | KV |

| 8 | 12 | 12 | M12*1.25 | 12 | 4 | 15 | 9.3 | M5 | 8 | 10 | M4 | 19 |

| 10 | 11.3 | |||||||||||

| 12 | 16 | 16 | M16*1.5 | 17 | 6 | 20 | 13.3 | 12 | M6 | 24 | ||

| 16 | 17.3 | |||||||||||

| 20 | 20 | 22 | M22*1.5 | 20 | 8 | 27 | 21.3 | G1/8 | 16 | 16 | M8 | 32 |

| 25 | 22 | 22 | 26.5 | M10*1.25 |

| Ø【mm】 | KW | L | L2 | MMØ | PL | VD | WF | XC ±1 | ZJ |

| 8 | 6 | 6 | 46 | 4 | 6 | 2 | 16 | 64 | 62 |

| 10 | |||||||||

| 12 | 8 | 9 | 50 | 6 | 22 | 75 | 72 | ||

| 16 | 56 | 82 | 78 | ||||||

| 20 | 11 | 12 | 68 | 8 | 8.2 | 24 | 95 | 92 | |

| 25 | 69.5 | 10 | 28 | 104 | 97.5 |

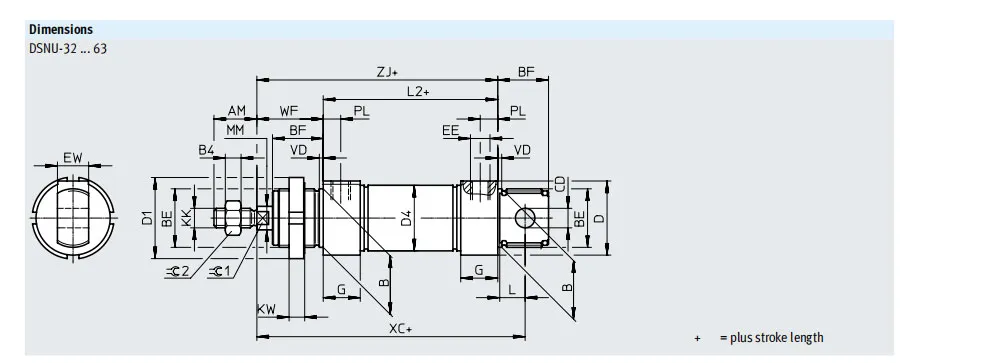

| Ø【mm】 | AM | B | B4 | BE | BF | CDΦ | DΦ | D1Φ | D4Φ | EE | EW | G | KK |

| 32 | 22 | 30 | 5 | M30X1.5 | 26 | 10 | 38 | 42 | 33.6 | G1/8 | 16 | 19 | M10X1.25 |

| 40 | 24 | 38 | 6 | M38X1.5 | 30 | 12 | 46 | 50 | 41.6 | G1/4 | 18 | 25 | M12X1.25 |

| 50 | 32 | 45 | 8 | M45X1.5 | 33 | 16 | 57 | 60 | 52.4 | 21 | M16X1.5 | ||

| 63 | 70 | 65.4 | G3/8 | 28 |

| Ø【mm】 | KW | L | L2 | MMØ | PL | VD | WF | XC ±1 | ZJ |

| 32 | 8 | 13 | 69.5 | 12 | 9 | 2 | 34 | 117.5 | 103.5 |

| 40 | 10 | 15 | 84.6 | 16 | 12 | 3 | 39 | 139.6 | 123.6 |

| 50 | 16 | 86.2 | 20 | 44 | 147.2 | 130.2 | |||

| 63 | 94.2 | 13 | 45 | 156.2 | 139.2 |

Installation and Maintenance

Installation

Select the appropriate cylinder variant and mounting accessories according to your machine setup.

Mount the cylinder securely using direct mounting or flange options to ensure alignment and stability.

Connect compressed air supply lines with appropriate fittings; ensure clean, dry air to maximize seal life.

Adjust pneumatic cushioning valves on both ends to optimize shock absorption based on load and speed.

If using magnetic piston variants, install proximity sensors aligned with the cylinder’s sensor slot.

Maintenance

Periodically check air supply cleanliness and pressure to prevent premature wear.

Inspect seals and piston rod for leaks or damage; replace seals as needed to maintain performance.

Keep the piston rod and cylinder exterior clean to avoid contamination and corrosion.

Avoid operating the cylinder beyond specified temperature and pressure limits.

Utilize manufacturer-recommended lubricants during maintenance or seal replacements, if applicable.

Detailed Applications

Automated Assembly Lines: Precision actuation for positioning parts and tools with high repeatability.

Electronics Manufacturing: Compact, reliable cylinders for delicate device assembly.

Packaging Equipment: Smooth, quiet motion for packing and sorting tasks.

Food and Beverage Industry: Corrosion-resistant construction suitable for hygienic environments.

Automotive Production: Durable cylinders for press-fit and component handling applications.

Medical Device Manufacturing: High precision and clean operation in small-scale automation.

How to Select the Right DSNU Mini Cylinder

Determine Bore Size and Stroke: Choose according to the required force and travel distance.

Select Cushioning Type: Adjustable or self-adjusting cushions provide options for application-specific shock absorption needs.

Consider Operating Environment: Stainless steel provides corrosion resistance; consider also the temperature and pressure specifications.

Position Sensing Requirements: Opt for magnetic piston models if position detection is required.

Mounting and Installation Needs: Verify compatibility with your machine mounting hardware.

Operating Pressure and Speed: Ensure the cylinder specifications suit your compressed air supply and cycle speed demands.

Request a Quote Now

Our team will get back to you within 24 hours.