The MAL Series mini pneumatic cylinder is a high-quality actuator designed for space-saving pneumatic automation solutions. Built with an aluminum alloy barrel and stainless steel piston rod, this 20mm bore cylinder provides smooth, efficient linear motion. The cylinder supports a double-acting mechanism, operating within a pressure range of 0.1 to 0.9 MPa, and accommodates strokes from 25mm to 500mm or customized lengths. Its sturdy construction ensures long service life, while its compact size makes it perfect for applications requiring precision and stability.

Main Features

Bore diameter: 20mm

Double-acting pneumatic cylinder

Aluminum alloy barrel with corrosion-resistant anodized surface

Stainless steel piston rod for durability and smooth movement

Stroke length options from 25mm to 500mm, customizable upon request

Operating pressure range: 0.1 to 0.9 MPa (working), up to 1.5 MPa guaranteed

Operating temperature range: -5°C to +70°C

Speed range: 30 to 800 mm/s

Multiple mounting types: Basic types LB, FA, SDB compatible

Port size options: M5x0.8, G1/8, G1/4

Available with magnetic piston for position sensing applications

Product Advantages

Lightweight but robust aluminum alloy construction enhances portability and installation

Corrosion-resistant barrel and rod ensure longevity in various industrial environments

Flexible stroke and mounting options meet diverse operational requirements

Magnetic piston option supports automation and control systems integration

Compact design fits tight spaces without compromising performance

Reliable double-acting mechanism for consistent motion and force output

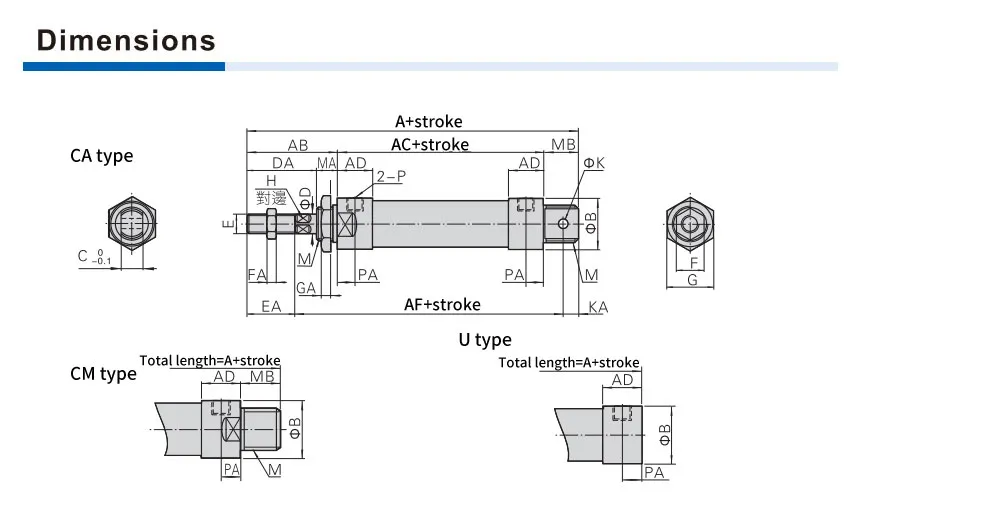

| Cylinder diameter | A | AB | AC | AD | AF | B | C | D | DA | M | MA | MB | ||||

| Rear cover from | CA | CM | U | CA | CM | |||||||||||

| 20 | 131 | 122 | 110 | 40 | 70 | 16 | 102 | 29 | 16 | 8 | 28 | M22 x 1.5 | 12 | 21 | 12 | |

| 25 | 135 | 128 | 114 | 44 | 70 | 16 | 104 | 34 | 16 | 10 | 30 | M22 x 1.5 | 14 | 21 | 14 | |

| 32 | 141 | 128 | 114 | 44 | 70 | 16 | 107 | 39.5 | 16 | 12 | 30 | M24x2.0 | 14 | 27 | 14 | |

| 40 | 165 | 152 | 138 | 46 | 92 | 22 | 129 | 49.5 | 20 | 16 | 32 | M30x2.0 | 14 | 27 | 14 | |

| Cylinder diameter | E | EA | F | FA | G | GA | H | K | KA | P | PA | |

| 20 | M8x1.25 | 20 | 12 | 6 | 29 | 7 | 6 | 8 | 9 | 1/8″ | 8 | |

| 25 | M10 x 1.25 | 22 | 17 | 6 | 29 | 7 | 8 | 8 | 9 | 1/8″ | 8 | |

| 32 | M10 x 1.25 | 22 | 17 | 6 | 32 | 8 | 10 | 10 | 12 | 1/8″ | 8 | |

| 40 | M12 x 1.25 | 24 | 17 | 7 | 41 | 9 | 14 | 12 | 12 | 1/4″ | 11 | |

Installation Steps and Maintenance

Confirm the required bore size, stroke length, and mounting style for the application.

Mount the cylinder securely using compatible brackets or mounting accessories as per the chosen type.

Connect clean, filtered compressed air to the proper ports (use 40µm filters recommended).

Adjust cushioning settings if applicable to minimize impact noise and wear.

Periodically inspect the piston rod and seals for wear or damage.

Lubricate the cylinder rod and seals as per manufacturer recommendations to maintain smooth operation.

Keep the exterior surfaces clean to prevent dust and debris accumulation.

For cylinders with magnetic sensors, check wiring and sensor health regularly to ensure accurate position feedback.

Detailed Applications

The MAL Series 20mm mini pneumatic cylinder is widely utilized in industries such as electronics assembly, semiconductor manufacturing, packaging machinery, robotic automation, and precision equipment. Its compact size and high precision are perfect for tasks requiring smooth and repetitive linear motion with limited installation space. Magnetic sensor variants are particularly suitable for automated systems requiring position feedback for enhanced control.

How to Choose the Right MAL Series Mini Pneumatic Cylinder

Determine the required bore size based on the force needed for the application. (20mm bore is ideal for light to moderate force tasks.)

Select appropriate stroke length according to the travel distance needed; customization is often available.

Decide on double-acting or single-acting depending on your application’s motion requirements.

Opt for magnetic piston variants if feedback or automation control is necessary.

Confirm the mounting style compatibility with your system (LB, FA, or SDB).

Check operating pressure and temperature compatibility with your working environment.

Consult technical datasheets or a product expert when in doubt to ensure optimal performance and safety.

Request a Quote Now

Our team will get back to you within 24 hours.