The MI Series compact pneumatic actuator is engineered to provide high-accuracy linear actuation with built-in magnetic piston sensing, ensuring real-time feedback and automation control. Constructed from corrosion-resistant stainless steel and equipped with a compact design, this mini cylinder suits applications requiring durability and precise position monitoring. Its magnetic sensor integration facilitates seamless communication with control systems, improving efficiency and reducing downtime in automated processes.

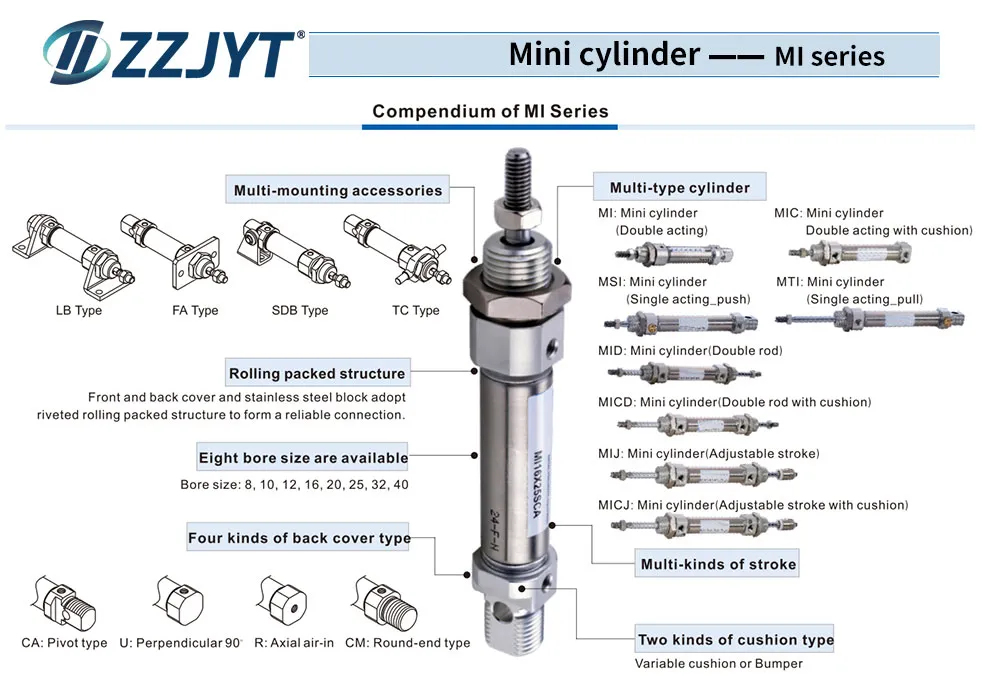

Main Features and Advantages

Compact stainless steel pneumatic actuator with bore sizes from 6mm to 25mm

Integrated magnetic piston sensor for reliable position sensing and control

Double-acting design for precise and consistent linear movement

Corrosion-resistant stainless steel construction for enhanced durability

Small size enables installation in confined spaces and tight automation setups

Adjustable cushioning reduces noise and mechanical shock during operation

Compatible with various mounting styles to suit different industrial needs

Suitable for a wide range of temperatures and environmental conditions

Detailed Applications

The MI Series actuator is widely used in automated assembly lines, electronics manufacturing, pharmaceutical equipment, laboratory automation, and food processing machinery. Its compact footprint and magnetic sensing make it ideal for precise positioning tasks in cleanroom and corrosive environments. Applications include pick-and-place systems, valve controls, packaging automation, and integration into smart factory systems with IoT connectivity.

| Bore size(mm) | 10 | 12 | 16 | 20 | 25 | 32 | 40 | ||

| Acting type | Double acting、Single_Push、Single acting_Pull | ||||||||

| Double acting with cushion | |||||||||

| Fluid | Air (to be filtered by 40 u m filter element) | ||||||||

| Operating pressure | Double acting | 0.15-1.0MPa(22-145psi)(1.5-10.0bar) | |||||||

| Single acting | 0.2-1.0MPa(28-145psi)(2.0-10.0bar) | ||||||||

| Proof pressure | 1.5MPa(215psil)(15bar) | ||||||||

| Temperature℃ | -20-70℃ | ||||||||

| Speed range mm/s | Double acting: 30-800 Single acting: 50-800 | ||||||||

| Cushion type | MIC Series: Variable cushion Other series:Bumper | ||||||||

| Port size [Note1] | M5×0.8 | 1/8″ | 1/4″ | ||||||

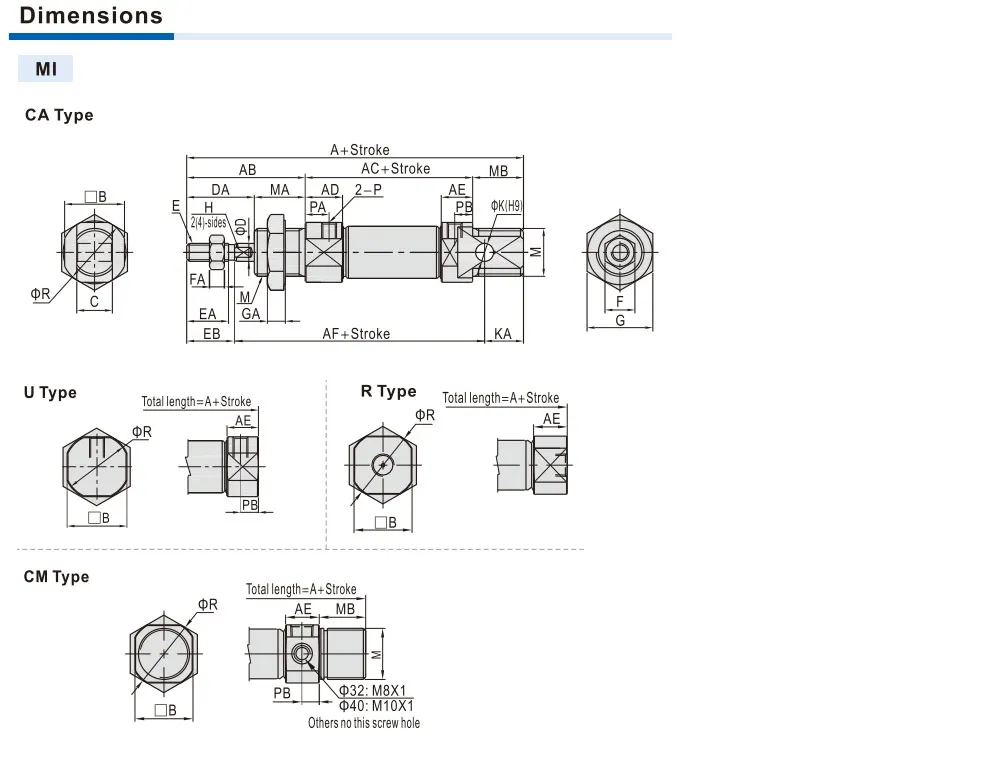

| Bore size/Item | A | AB | AC | AD | AE | AF | B | C | D | DA | E | EA | EB | ||||

| Back cover | CA | U | R | CM | CA | U/R/CM | |||||||||||

| 8 | 86 | 74 | – | – | 28 | 46 | 11.5 | 9.5 | 9.5 | 64 | 15 | 8 | 4 | 16 | M4*0.7 | 10.5 | 12 |

| 10 | 86 | 74 | – | – | 28 | 46 | 11.5 | 9.5 | 9.5 | 64 | 15 | 8 | 4 | 16 | M4*0.7 | 10.5 | 12 |

| 12 | 105 | 88 | – | – | 38 | 50 | 12.5 | 10.5 | 10.5 | 75 | 18 | 12 | 6 | 21 | M6*1.0 | 14.5 | 16 |

| 16 | 111 | 94 | 94 | 111 | 38 | 56 | 12.5 | 10.5 | 10.5 | 82 | 20 | 12 | 6 | 21 | M6*1.0 | 14.5 | 16 |

| 20 | 126 | 106 | 106 | 126 | 44 | 62 | 14.5 | 14.5 | 14.5 | 95.5 | 25 | 16 | 8 | 24 | M8*1.25 | 18 | 19.5 |

| 25 | 137 | 114.5 | 115 | 137 | 50 | 65 | 16 | 16 | 16 | 104.5 | 30 | 16 | 10 | 28 | M10*1.25 | 20 | 21.5 |

| 32 | – | 125 | 126 | 140 | 58 | – | – | – | 16.5 | – | 34.5 | – | 12 | 28 | M10*1.25 | 18.5 | 20 |

| 40 | – | 158 | 158 | 174 | 69 | – | – | – | 22 | – | 42.5 | – | 16 | 34 | M12*1.25 | 22.5 | 24 |

| Bore size/Item | F | FA | G | GA | H | K | KA | M | MA | MB | P | PA | PB | R | |

| Back cover | CA | U/CM | |||||||||||||

| 8 | 7 | 3 | 17 | 6 | – | 4 | 10 | M12*1.25 | 12 | 12 | M5*0.8 | 7 | 5 | 5 | 17 |

| 10 | 7 | 3 | 17 | 6 | – | 4 | 10 | M12*1.25 | 12 | 12 | M5*0.8 | 7 | 5 | 5 | 17 |

| 12 | 10 | 5 | 22 | 6 | 5(2-Sides) | 6 | 14 | M16*1.5 | 17 | 17 | M5*0.8 | 8 | 6 | 6 | 20 |

| 16 | 10 | 5 | 22 | 6 | 5(2-Sides) | 6 | 13 | M16*1.5 | 17 | 17 | M5*0.8 | 8 | 6 | 6 | 22 |

| 20 | 12 | 6 | 29 | 7 | 6(2-Sides) | 8 | 11 | M22*1.5 | 20 | 20 | 1/8″ | 7.5 | 7.5 | 7.5 | 29 |

| 25 | 17 | 6 | 29 | 7 | 8(4-Sides) | 8 | 11 | M22*1.5 | 22 | 22 | 1/8″ | 8 | 8 | 8 | 33.5 |

| 32 | 17 | 6 | 36 | 7 | 10(4-Sides) | – | – | M30*1.5 | 30 | 14 | 1/8″ | 9 | – | 8/9 | 37.5 |

| 40 | 17 | 7 | 46 | 8 | 14(4-Sides) | – | – | M38*1.5 | 35 | 16 | 1/4″ | 12 | – | 11.5/12 | 46.5 |

Installation Steps and Maintenance

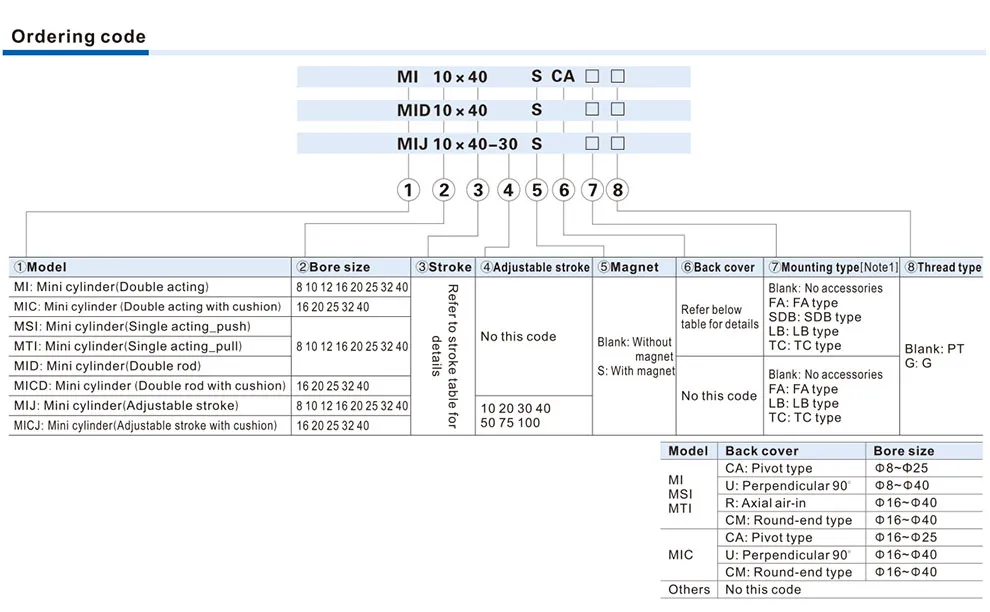

Select the appropriate bore size and stroke length based on required force and travel distance.

Choose the mounting style compatible with your setup (e.g., foot mount, flange mount, or rod end).

Connect pneumatic lines with clean, dry air supply to prevent contamination.

Ensure magnetic sensor wiring is correctly installed and tested within the control system.

Adjust cushioning settings to optimize performance and minimize wear.

Regularly inspect seals, sensor connections, and piston rod for wear or damage.

Lubricate where recommended, based on operating frequency and environmental conditions.

Keep the actuator clean and free from dust or corrosive substances to extend service life.

How to Choose the Right MI Series Pneumatic Actuator

Determine required bore size and stroke length based on application load and movement range.

Verify if magnetic sensor feedback is needed for automation and control precision.

Consider environment – stainless steel models are preferred for corrosive, cleanroom, or humid applications.

Decide on mounting style according to machine integration and space constraints.

Choose between standard and adjustable cushioning based on noise and shock requirements.

Ensure compatibility with existing pneumatic and sensor control systems.

Request a Quote Now

Our team will get back to you within 24 hours.