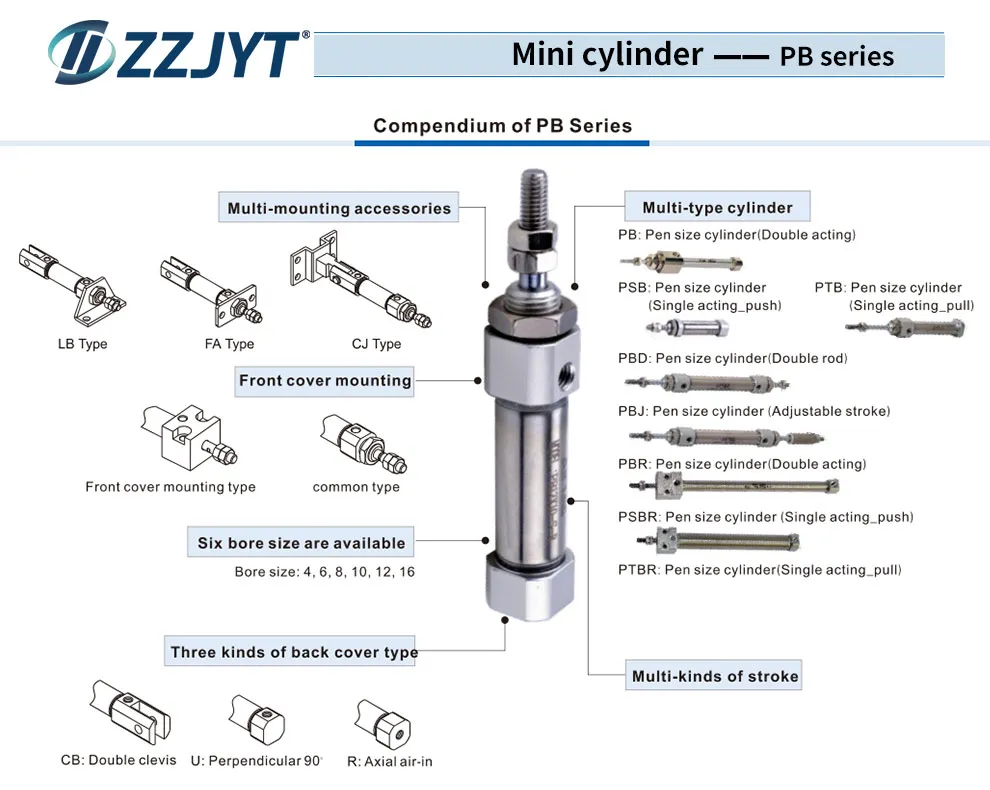

The PB Series mini cylinder is engineered to deliver precise and stable linear motion in various automation environments. Featuring a compact design and high-quality materials, this pneumatic actuator provides consistent performance even in demanding conditions. Its precision construction reduces air leakage and ensures smooth piston operation, essential for tight tolerance applications in manufacturing, assembly, and other automated processes.

Main Features and Advantages

Compact design optimized for space-saving automation setups

Precision-machined components for reduced internal leakage and consistent performance

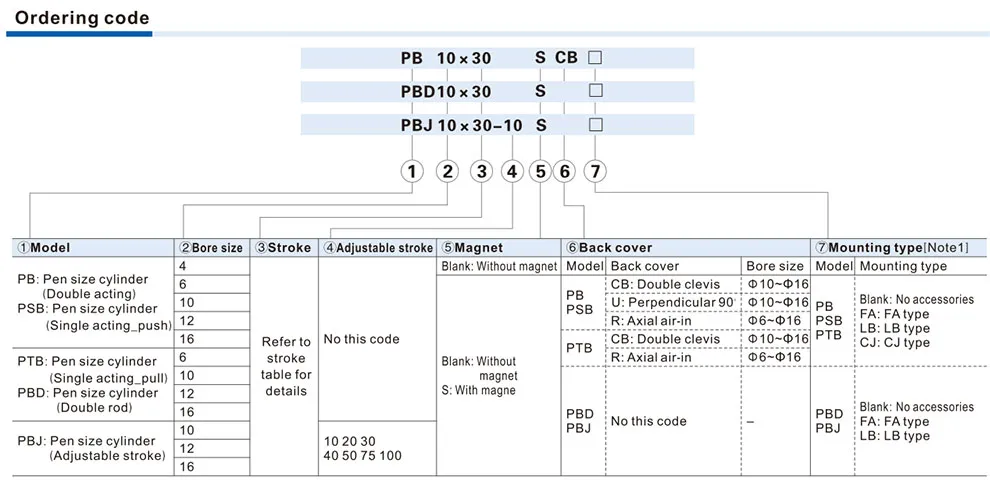

Available in various bore sizes and stroke lengths to tailor fit specific automation needs

Double acting cylinder design for controlled forward and return motions

High abrasion-resistant seals enhancing cylinder lifespan and reliability

Corrosion-resistant materials suitable for diverse industrial environments

Compatible with magnetic piston position sensors for automation feedback

Easy installation with standard mounting options and accessories

Detailed Applications

The PB Mini Cylinder is widely used in precision automation such as electronics assembly, packaging machinery, medical device manufacturing, and laboratory equipment. Its stable and precise actuation is perfect for pick-and-place mechanisms, valve control, material handling, and small-scale robotic arms. The inclusion of position sensing supports integration into smart factory setups for real-time process control.

| Bore size(mm) | 4 | 6 | 10 | 12 | 16 | |||

| Acting type | Double acting、Single acting_Push | Double acting、Single acting | ||||||

| Fluid | Air(to be filtered by 40 μ m filter element) | |||||||

| Operating pressure | Double acting | 0.2~0.7MPa(28~100psi)(2.0~7.0bar) | 0.15~0.7MPa(22~100psi)(1.5~7.0bar) | |||||

| Single acting | 0.3~0.7MPa(36~100psi)(3.0~7.0bar) | 0.2~0.7MPa(28~100psi)(2.0~7.0bar) | ||||||

| Proof pressure | 1.2MPa(175psi)(12bar) | |||||||

| Temperature ℃ | -20~70 | |||||||

| Speed range mm/s | 50~500 | 50~800 | ||||||

| Cushion type | No cushion | Bumper | ||||||

| Port size | Tube | M5×0.8 | ||||||

| Add) Refer to P353 for detail of sensor switch. | ||||||||

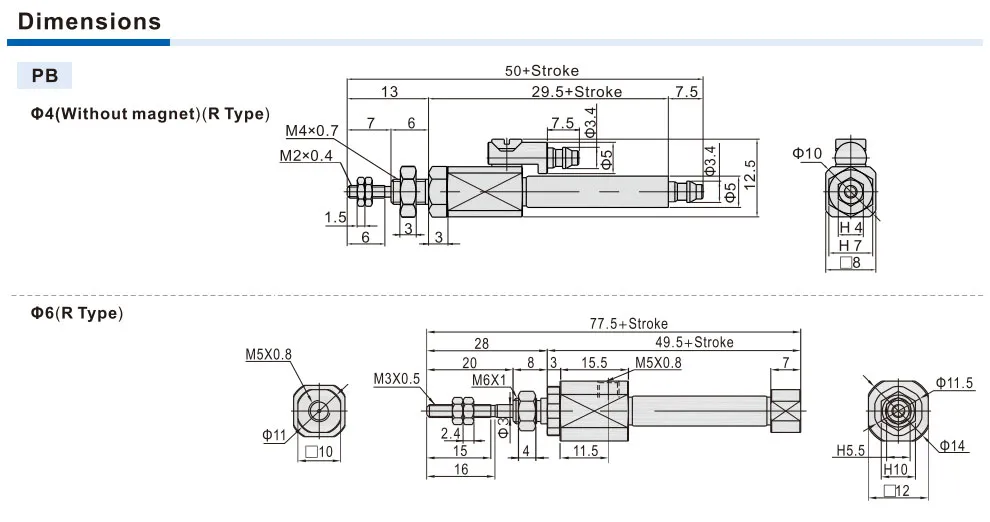

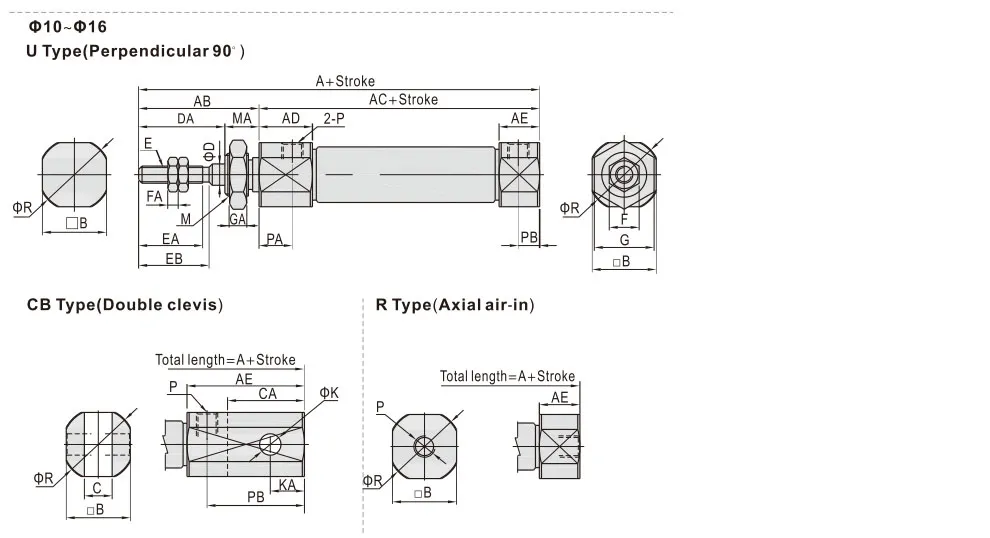

| Bore size/Item | A | AB | AC | AD | AE | B | C | CA | D | DA | E | EA | EB | F | ||||

| Back cover | U | CB | R | U/R | CB | |||||||||||||

| 10 | 74 | 87 | 74 | 28 | 46 | 11.5 | 9.5 | 22.5 | 12 | 3.3 | 13 | 4 | 20 | M4*0.7 | 15 | 16.5 | 7 | |

| 12 | 74 | 92 | 74 | 28 | 46 | 11.5 | 9.5 | 27.5 | 15 | 6.6 | 18 | 5 | 20 | M5*0.8 | 15 | 16.5 | 8 | |

| 16 | 76 | 94 | 76 | 28 | 48 | 12 | 9.5 | 27.5 | 18 | 6.6 | 18 | 5 | 20 | M5*0.8 | 15 | 16.5 | 8 | |

| Bore size/Item | FA | G | GA | K | KA | M | MA | P | PA | PB | R | ||

| Back cover | U | CB | |||||||||||

| 10 | 3 | 11 | 4 | 3.3 | 5 | M8*1.0 | 8 | M5*0.8 | 7.5 | 5 | 18 | 14 | |

| 12 | 4 | 14 | 4 | 5 | 8 | M10*1.0 | 8 | M5*0.8 | 7.5 | 5 | 23 | 17 | |

| 16 | 4 | 14 | 4 | 5 | 8 | M10*1.0 | 8 | M5*0.8 | 7.5 | 5 | 23 | 20 | |

Installation Steps and Maintenance

Determine the required bore size and stroke length based on application specifications.

Choose compatible mounting brackets or fixtures to securely install the cylinder.

Connect clean, filtered air supply lines to ensure smooth operation and prevent contamination.

Install magnetic sensors if position monitoring is needed and verify electrical connections.

Adjust cushioning settings to reduce noise and mechanical impact during operation.

Regularly inspect seals, piston rods, and magnetic sensors for wear or damage.

Follow manufacturer recommendations for lubrication intervals, especially during high-cycle use.

Clean the exterior regularly to prevent buildup of dust and debris.

How to Choose the Right PB Mini Cylinder

Assess the force requirements and select the appropriate bore size.

Define the stroke length needed for the automation task.

Decide whether magnetic sensor feedback is necessary for process control.

Consider environmental factors and select materials (e.g., corrosion resistance).

Choose mounting type compatible with your machinery and workflow.

Confirm pneumatic system compatibility including pressure and flow requirements.

Request a Quote Now

Our team will get back to you within 24 hours.