The MBB Series aluminum alloy mini cylinder is designed to meet demanding industrial requirements with a focus on strength, lightweight design, and versatility. Manufactured with high-grade aluminum alloy and precision machining, this standard pneumatic cylinder supports double-acting, single-rod configurations with enhanced cushioning to reduce noise and vibration. Its compact design, combined with reduced weight due to innovative rod and head cover shape modifications, ensures easier installation and improved energy efficiency.

Main Features

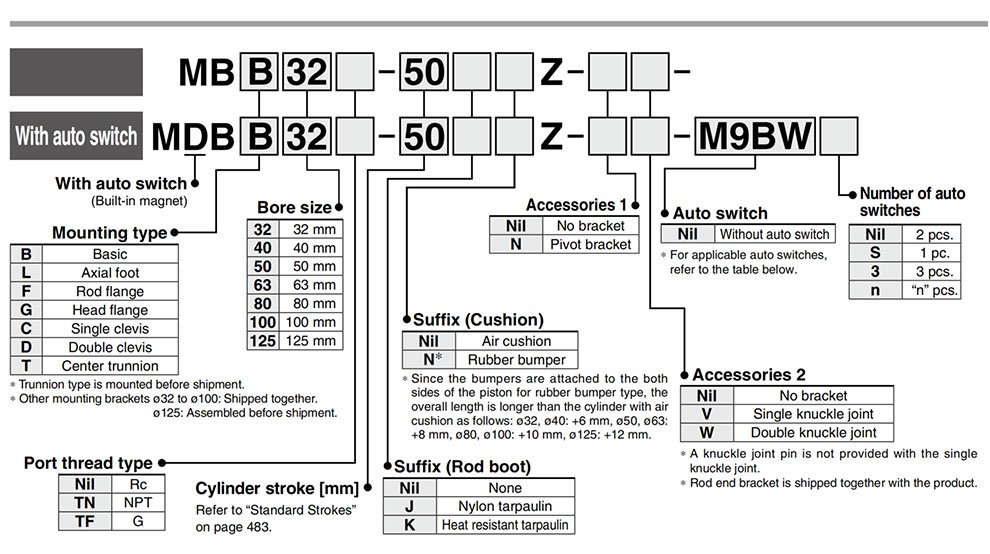

Bore sizes available: 32, 40, 50, 63, 80, 100 mm

Double-acting, single-rod pneumatic cylinder

Aluminum alloy body with anodized finish for corrosion resistance

Adjustable cushioning pads at cylinder ends for smooth operation

Lightweight design with up to 10% weight reduction via optimized rod and head covers

Standard mounting dimensions compatible with SMC specifications

Wide operating temperature range suitable for most industrial environments

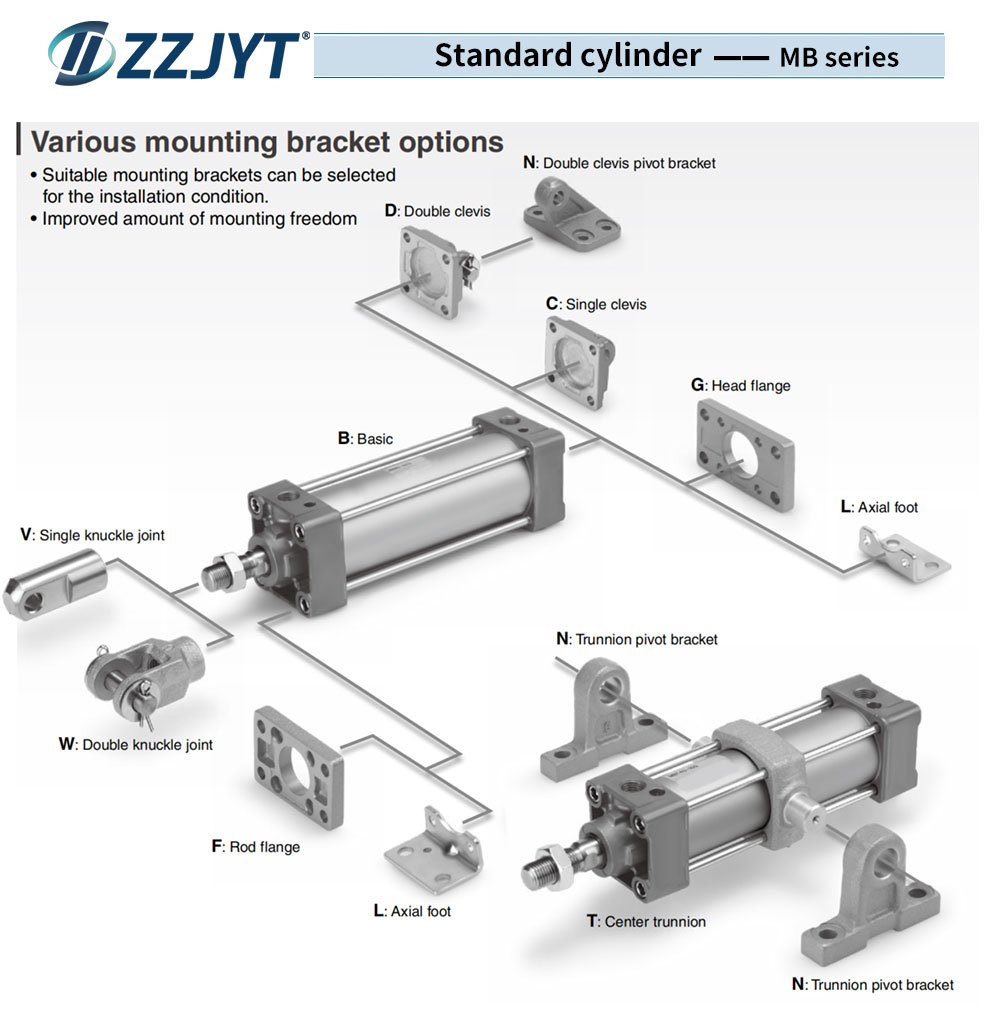

Various mounting options including brackets and end locks available

Compatible with magnetic sensors for position detection

Product Advantages

Durable aluminum alloy construction offers excellent strength-to-weight ratio

Reduced cylinder weight improves system efficiency and ease of handling

Adjustable cushioning minimizes operational noise and wear, extending cylinder life

Precise machining ensures optimal seal performance and leak reduction

Standardized mounting dimensions simplify system design integration

Suitable for automation, packaging, material handling, and manufacturing industries

Available in multiple bore sizes to meet diverse application force and stroke needs

| Bore size[mm] | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

| Action | Double acting, Single rod | ||||||

| Fluid | Air | ||||||

| Proof pressure | 1.5 MPa | ||||||

| Maximum operating pressure | 1.0 MPa | ||||||

| Minimum operating pressure | 0.05 MPa | ||||||

| Ambient and fluid temperature | Without auto switch: 0 to 70°C With auto switch: 0 to 60°C (No freezing) | ||||||

| Lubricant | Not required (Non-lube) | ||||||

| Piston speed | 50 to 1000 mm/s | ||||||

| Cushion | Air cushion or Rubber bumper | ||||||

| Port size (Rc) | 1/8 | 1/4 | 3/8 | 1/2 | |||

| Mounting | Basic, Axial foot, Rod flange, Head flange Single clevis, Double clevis, Center trunnion | ||||||

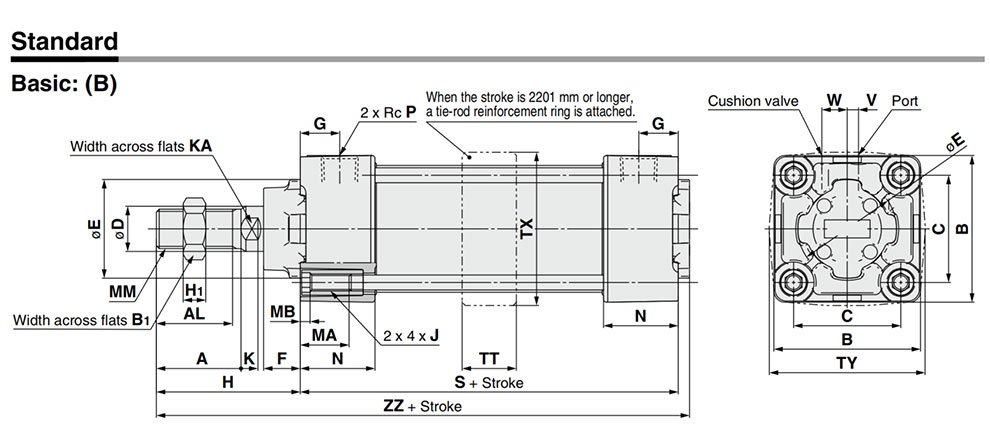

| Bore size[mm] | A | AL | B | B1 | C | D | E | F | G | H | H1 | J | K | KA | MA | MB | MM | N | P | S | TT | TX | TY | V | W | ZZ |

| 32 | 22 | 19.5 | 46 | 17 | 32.5 | 12 | 30 | 13 | 13 | 47 | 6 | M6X1 | 6 | 10 | 16 | 4 | M10X1.25 | 27 | 1/8 | 84 | 17 | 48 | 49 | 4 | 6.5 | 135 |

| 40 | 30 | 27 | 52 | 22 | 38 | 16 | 35 | 13 | 14 | 51 | 8 | M6X1 | 6 | 14 | 16 | 4 | M14X1.5 | 27 | 1/4 | 84 | 22 | 55 | 58 | 4 | 9 | 139 |

| 50 | 35 | 32 | 65 | 27 | 46.5 | 20 | 40 | 14 | 15.5 | 58 | 11 | M8X1.25 | 7 | 18 | 16 | 5 | M18X1.5 | 31.5 | 1/4 | 94 | 22 | 68 | 71 | 5 | 10.5 | 156 |

| 63 | 35 | 32 | 75 | 27 | 56.5 | 20 | 45 | 14 | 16.5 | 58 | 11 | M8X1.25 | 7 | 18 | 16 | 5 | M18X1.5 | 31.5 | 3/8 | 94 | 28 | 81 | 81 | 9 | 12 | 156 |

| 80 | 40 | 37 | 95 | 32 | 72 | 25 | 45 | 20 | 19 | 72 | 13 | M10X1.5 | 10 | 22 | 16 | 5 | M22X1.5 | 38 | 3/8 | 114 | 34 | 102 | 102 | 11.5 | 14 | 190 |

| 100 | 40 | 37 | 114 | 41 | 89 | 30 | 55 | 20 | 19 | 72 | 16 | M10X1.5 | 10 | 26 | 16 | 5 | M26X1.5 | 38 | 1/2 | 114 | 40 | 124 | 124 | 17 | 15 | 190 |

| 125 | 54 | 50 | 136 | 41 | 110 | 32 | 60 | 27 | 19 | 97 | 16 | M12X1.75 | 13 | 27 | 20 | 6 | M27X2 | 38 | 1/2 | 120 | 50 | 148 | 148 | 17 | 15 | 223 |

Installation Steps and Maintenance

Verify cylinder bore and stroke specifications to match application requirements.

Use compatible mounting brackets or end locks for secure fixture placement.

Connect air supply lines using clean, filtered air to prevent contamination.

Adjust cushioning pads as necessary to minimize load impacts and vibration.

Regularly inspect seals and piston rod for signs of wear or leakage.

Lubricate moving parts periodically according to manufacturer guidelines.

Keep cylinder body and rod clean to prevent dust or debris interference.

If equipped with magnetic sensors, inspect wiring and sensor functionality regularly.

Detailed Applications

The MBB Series aluminum alloy mini cylinder finds extensive use across automation systems, pneumatic tooling, packaging machines, conveyor drives, and light manufacturing equipment. Its compact size and high thrust capability make it an excellent choice for assembly lines, material transfer, clamping mechanisms, and other pneumatic actuation tasks where space and weight savings are crucial. The standardized mounting and sensor compatibility further support integration into automated control systems.

Request a Quote Now

Our team will get back to you within 24 hours.