Definition and function of copper barb connector

The copper barb connector, typically made from copper alloy materials like brass, is a versatile accessory for pipe connections. It features an insertion end with a barb and a connection end, allowing it to link flexible pipes, such as plastic hoses and rubber tubes, with metal fittings or equipment.

The barb connector works by inserting the barb into the hose, leveraging the hose’s elastic deformation to create a secure mechanical buckle on the inner pipe wall. This results in a quick and reliable connection. The connection end is usually threaded internally or externally, enabling it to connect with standard fittings like valves and joints.

Copper barb connectors offer excellent mechanical strength and corrosion resistance, making them a popular choice in fluid delivery systems, including air compressor lines, water cooling systems, and gas pipelines. They simplify pipeline assembly and maintenance, making them an ideal option for connecting hoses to rigid pipes.

Main components

Design and function of the barb

- The barb is a key structure of the copper connector, usually with 1-2 annular protrusions, similar to the shape of a fishhook or arrow. The size of the barb needs to match the inner diameter of the hose. After insertion, it will be stuck to the pipe wall through elastic deformation to prevent it from falling off.

- The surface of the barb is smooth and the edge is rounded to avoid scratching the inner wall of the hose. A reasonable barb design can withstand a certain amount of tension and can be pulled out when needed, which is convenient for pipeline disassembly.

Connector body material

- The connector body is mostly made of copper alloy materials such as brass and bronze. They have high strength, good corrosion resistance, strong machinability, and can meet the requirements of most working conditions.

- For special applications, materials such as stainless steel and engineering plastics can also be used to improve high temperature resistance and chemical resistance.

The importance of sealing rings

- In order to ensure good sealing performance, copper barb connectors are usually equipped with elastic sealing elements such as O-rings. They are installed inside the connector to fill the gap and prevent medium leakage.

- Common sealing ring materials include nitrile rubber (NBR), fluororubber (FKM), etc., which can be selected according to the characteristics of the medium. Regularly checking the integrity and elasticity of the seal ring and replacing it in time when necessary is crucial to ensure the safety of the system.

Types of fastening devices

- In order to fix the hose and prevent it from falling off under high pressure, the copper barb connector is usually equipped with a fastening device. Common types include compression hoop type and clamp type.

- The compression hoop type uses bolts to press the metal hoop on the outer periphery of the hose; the clamp type has a notch in the hoop body and is inserted into the annular groove during installation. After tightening, the hose is evenly squeezed and is not easy to loosen or deform.

Applicable pipes and scenarios for copper barb connectors

Applicable Pipes

- Metal Pipes: Copper barb connectors can also be used with metal hoses, such as stainless steel. While metal pipes are strong and resistant to high pressure, the pipe ends can easily damage the barb surface during assembly, affecting the seal, so caution is advised.

- PVC Pipes: Copper barb connectors can effectively connect PVC pipes, offering flexible assembly and reliable sealing. However, PVC pipes are relatively rigid, so care must be taken during assembly and disassembly to avoid damaging the barbs.

- PE Pipes: These pipes are lightweight and flexible, commonly used for transporting hot and cold water. Copper barbs can connect PE pipes efficiently, but it’s crucial to ensure the working temperature is not too high, as PE pipes may soften and deform.

Application Scenarios

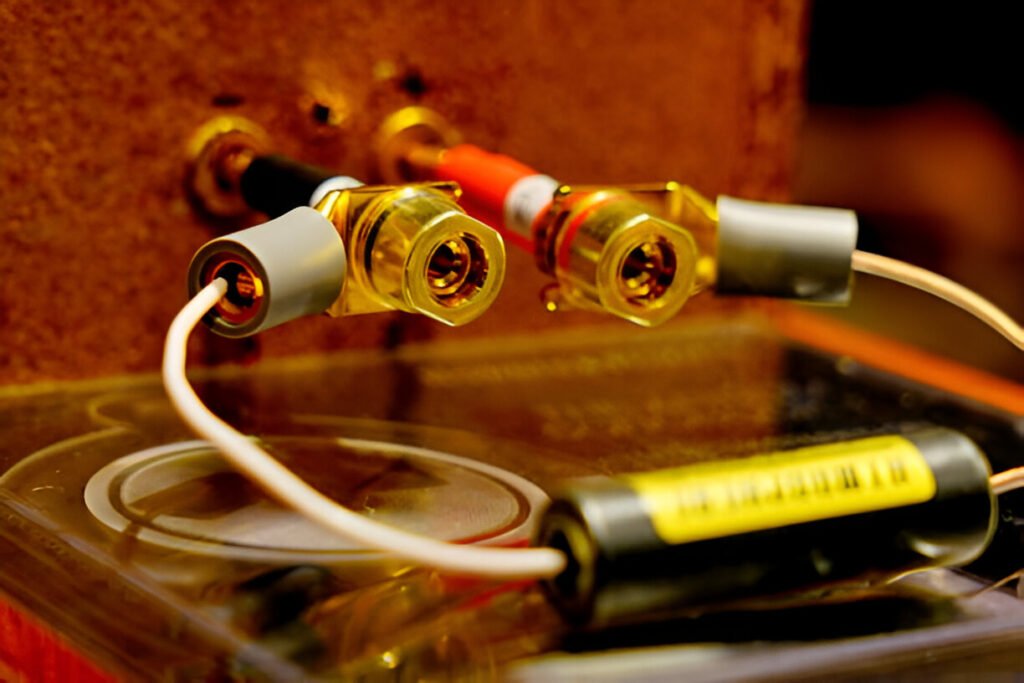

- Compressed Air Systems: Copper barb connectors are often used to link air compressors with gas tanks and pneumatic tools, facilitating the transmission of compressed air.

- Water-Cooled Equipment: They connect cooling water pipelines to transport coolant, ensuring efficient heat management.

- Gas Stove Connections: Copper barbs are utilized to connect gas hoses with stoves, safely transporting gas. In these scenarios, selecting the appropriate connector specifications and materials based on working conditions is essential for ensuring safety and reliability.

Different types of application scenarios

Barb connectors are versatile and can be used in a variety of application scenarios, each with its own specific requirements and benefits.

Types of Barb Connectors and Their Applications

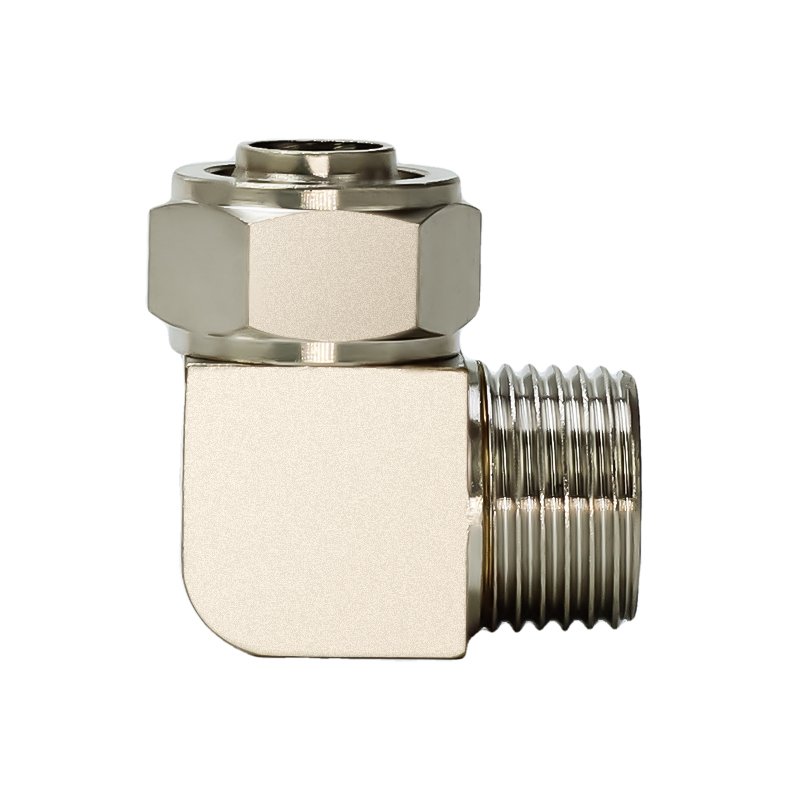

- Straight-Through Barb Connectors: These are the most common type, featuring a barb and a thread at each end. They are used to connect hoses to valves and joints, providing a straightforward and reliable connection in systems like plumbing, industrial fluid transfer, and automotive applications.

- Angled Barb Connectors (Elbow Barb Connectors): These connectors allow for a 90-degree turn in the pipeline, which is useful for navigating corners or obstacles in installations. They save space and provide flexibility in design, making them suitable for irrigation systems and other applications where directional changes are needed.

- Three-Way and Four-Way Barb Connectors: These connectors enable the confluence of multiple pipelines, allowing for the distribution of fluids from one main line to several branch lines. While they offer greater flexibility, the increased number of interfaces raises the risk of leakage, requiring extra caution during assembly.

Application Scenarios

Medical Equipment: Barb connectors are used in medical devices for fluid transfer, providing a reliable connection in critical applications.

Plumbing Systems: Barb connectors are widely used in residential and commercial plumbing to connect hoses and pipes securely, preventing leaks and ensuring reliable water supply and drainage.

Industrial Applications: They are used in manufacturing for pneumatic and hydraulic systems, facilitating the transfer of air, gas, or fluids.

Automotive and Marine: Barb connectors are used in fuel lines, cooling systems, and ventilation systems due to their ability to withstand harsh conditions and maintain a tight seal.

Irrigation and Agriculture: They are essential in irrigation systems for connecting hoses and drip tubing, ensuring efficient water and nutrient delivery.

Considerations when choosing copper barb connectors

Material requirements

Choose the appropriate connector material according to the characteristics of the conveying medium. For example, when conveying drinking water, lead-free copper alloy should be used; when conveying corrosive liquids, stainless steel or engineering plastic materials can be used.

Size and specification matching

The barb size of the connector should match the inner diameter of the hose. Too large or too small will affect the sealing and firmness. The thread specifications should match the valve and connector, otherwise it cannot be assembled.

The influence of barb design

Design parameters such as the number, height, and angle of the barbs will affect the connection strength. Single barbs are suitable for softer pipes, and double barbs have stronger tensile strength and are suitable for harder pipes. However, too dense barbs will also damage the pipe, which needs to be weighed.

The importance of sealing performance

Pay attention to the sealing performance of the connector. Choose the appropriate sealing material and check the integrity of the sealing ring. Try to choose a connector with a fastening device to eliminate leakage risks from the source.

Corrosion resistance considerations

When conveying corrosive media, choose a connector material with good corrosion resistance, such as stainless steel, engineering plastics, etc. At the same time, the surface of the connector should be flat and smooth to avoid corrosion gaps. Check the corrosion condition of the connector regularly and replace damaged parts in time.