Guide cylinder play an irreplaceable role in modern industrial automation. Have you ever wondered why some cylinders can maintain precise linear motion even when subjected to significant lateral forces? The answer lies in the design. As an important branch of pneumatic actuators, guide cylinder not only improve the stability and durability of equipment but also greatly expand the range of cylinder applications. Today, let’s take a closer look at what a guide cylinder is, how it works, and why it has become the “unsung hero” on automated production lines.

What Is a Guide Cylinder and How Does It Work?

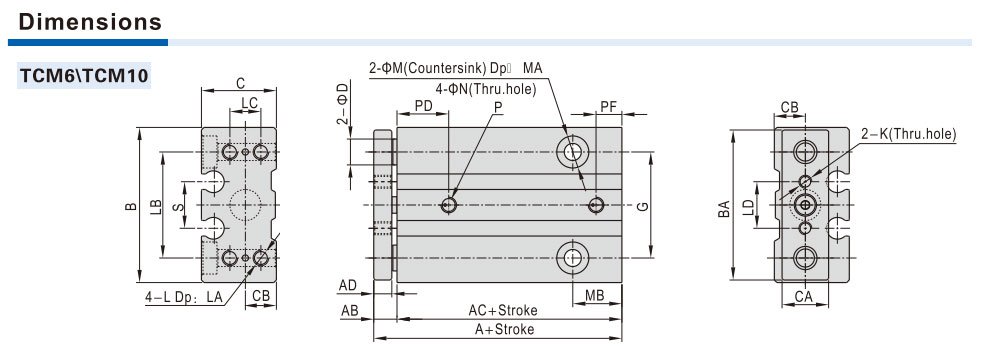

As the name suggests, a guide cylinder is a type of pneumatic cylinder equipped with a guiding mechanism. Its core structure includes the cylinder body and one or more guide rods. These guide rods restrict the lateral movement and rotation of the piston rod. In simple terms, the cylinder uses guide rods to ensure that the piston rod moves along a predetermined straight line, preventing the misalignment or bending that can occur with standard cylinders under side loads.

When in operation, the piston inside the cylinder moves the piston rod back and forth under air pressure. The guide rods act like “guardrails,” keeping the piston rod stable. This means that even under heavy side loads, the can maintain a high-precision motion path.

Key Features and Advantages of Guide Cylinders

What makes guide cylinders stand out? Here are some key points:

- High Load Capacity: Compared to standard cylinders, guide cylinders can withstand greater side forces and torque, making them ideal for heavy-duty applications.

- Precise Linear Motion: The guide rods effectively prevent the piston rod from rotating or shifting, ensuring stable and accurate movement.

- Compact Structure: Smart design saves space and makes installation easy on various types of automation equipment.

- Versatile Mounting Options: Multiple mounting options allow for flexible adaptation to different machine layouts.

These features make guide cylinders a top choice for tasks like automated assembly, clamping, and material pushing.

Common Types and Applications of Guide Cylinders

Did you know that guide cylinders have their own “family members”? Here are a few common types:

- Guide Rod Cylinder: The most common type, equipped with one or more pairs of guide rods, suitable for most applications.

- Compact Guide Cylinder: Small and space-saving, perfect for tight installation spaces.

- Dual-rod Guide Cylinder: Two parallel guide rods provide even more stability and load capacity.

Guide cylinders are widely used in automated assembly lines, stamping machines, material handling, clamping devices, and more. For example, in stamping operations, a guide cylinder ensures the punch is positioned accurately, preventing equipment damage.

Guide Cylinder vs. Standard Cylinder

Let’s make a quick comparison to see how guide cylinders differ from standard cylinders:

| Feature | Guide Cylinder | Standard Cylinder |

|---|---|---|

| Side Load Capacity | High, withstands significant forces | Low, easily damaged by side loads |

| Anti-rotation | Excellent, guide rods prevent rotation | Poor, piston rod may rotate |

| Motion Accuracy | High, ensures linear movement | Average, may drift |

| Structural Complexity | More complex, with guide mechanism | Simple, compact structure |

| Application Scenarios | High-precision, heavy-load, complex tasks | Light-duty, simple linear motion |

How to Choose the Right Guide Cylinder

Don’t just look at the price when choosing a guide cylinders! Here are a few factors that matter more:

- Load Capacity: Determine the maximum side force and thrust the cylinder will need to handle.

- Installation Space: Measure available space and choose between compact or standard types.

- Precision Requirements: For high-precision needs, select cylinders with enhanced guide rods.

- Stroke Length: Pick the right stroke length for your application.

- Mounting Options: Consider whether the mounting method fits your equipment design.

If you’re looking for advice on “guide cylinders selection” or “high-precision cylinder applications,” we’re happy to help you customize the perfect solution.

A guide cylinders is more than just a component in a pneumatic actuator-it’s the guardian of efficient and precise automation. If you’re looking for high-quality, reliable Pneumatic Actuator, get in touch with us. Whether you need standard models or custom solutions, we’re ready to provide professional support.

Don’t hesitate! Send us your inquiry now and let’s take your automation equipment to new heights of efficiency and precision!

FAQ

What are the main advantages of using a guide cylinder?

Guide cylinders offer high load capacity, precise linear motion, and excellent resistance to side forces. They also help reduce wear on seals and bearings, which extends the cylinder’s lifespan.

Where are guide cylinders commonly used?

Guide cylinders are widely used in automation, material handling, clamping, stamping, and any application that requires high accuracy and repeatability, especially when side or off-center loads are present.

Can the stroke length of a guide cylinder be adjusted?

Yes, many guide cylinders allow you to adjust the stroke length to fit specific requirements, making them flexible for different applications.

How do I maintain a guide cylinder?

Regularly lubricate the guide rods and piston rod, keep the components clean, and check seals for wear. Proper maintenance helps prevent breakdowns and extends the cylinder’s service life.

Why choose a guide cylinder over a standard cylinder?

Guide cylinders provide better alignment, higher accuracy, and can handle greater side loads than standard cylinders, making them ideal for demanding industrial tasks.